How to apply UV DTF wrap is a skill that's becoming increasingly valuable, given the global market for personalized gifts is experiencing a significant surge, projected to reach USD 54.15 billion by 2033, exhibiting a CAGR of 6.7% during the forecast period, according to a recent report. This growth underscores the increasing demand for unique, custom items, and UV DTF wraps are at the forefront of this trend. Mastering the application of these vibrant, durable decals is crucial for crafters and businesses alike. This guide will provide you with the professional techniques needed to apply UV DTF wraps flawlessly, ensuring your creations stand out.

What is UV DTF Wrap?

UV DTF (Ultraviolet Direct-to-Film) wrap is a pre-printed decal that utilizes UV-curable ink. Designs are printed onto a special film, cured with UV light, and then transferred onto various smooth surfaces. This process results in vibrant, durable, and long-lasting designs that are resistant to scratches, fading, and water damage.

Why is UV DTF Wrap so popular?

Durability: Tough and Long-Lasting

-

Scratch Resistance: The UV-cured ink creates a robust, scratch-resistant finish that can withstand daily wear and tear.

-

Weather Resistance: UV DTF wraps are resistant to fading from sunlight and damage from moisture, making them suitable for both indoor and outdoor applications.

-

Adhesion: The strong adhesive ensures the wraps adhere securely to surfaces, preventing peeling or lifting over time.

Vibrancy: Vivid and Eye-Catching

-

Color Saturation: The printing process produces highly saturated colors that remain vibrant and true to the original design.

-

Detail Reproduction: UV DTF technology allows for the reproduction of intricate details and fine lines with exceptional clarity.

-

Gloss Finish: The cured ink creates a glossy finish that enhances the visual appeal of the designs.

Versatility: Applicable to Various Surfaces

-

Material Compatibility: UV DTF wraps can be applied to a wide range of smooth, non-porous surfaces, including glass, metal, plastic, and ceramic.

-

Shape Conformity: The flexible nature of the wraps allows them to conform to curved or irregular surfaces with ease.

-

Size Options: UV DTF wraps can be produced in various sizes, from small decals to large-format wraps.

Ease of Use: Simple and Efficient Application

-

Straightforward Process: Applying UV DTF wraps is a relatively simple process that requires minimal tools or expertise.

-

Quick Application: The wraps can be applied quickly and efficiently, reducing production time.

-

Bubble-Free Application: The smooth, adhesive backing helps prevent air bubbles from forming during application.

Professional Finish: High-Quality and Polished Look

-

Seamless Appearance: UV DTF wraps create a seamless appearance that looks like the design is printed directly onto the surface.

-

High-Resolution Prints: The printing process produces high-resolution prints with sharp details and smooth gradients.

-

Commercial-Grade Quality: UV DTF wraps offer a professional, commercial-grade finish that enhances the value of customized products.

How can crafters benefit from UV DTF Wrap?

Personalized Gifts: Craft Thoughtful and Unique Presents

-

Customized Mugs and Tumblers: Create personalized drinkware with names, monograms, or special messages for birthdays, holidays, or weddings.

-

Personalized Phone Cases: Design unique phone cases with photos, artwork, or quotes that reflect the recipient's personality.

-

Customized Home Decor Items: Add personalized touches to home decor items like coasters, picture frames, or vases.

-

Personalized Accessories: Create customized accessories like keychains, jewelry boxes, or makeup bags.

Custom Products: Expand Your Product Lines and Offer Unique Items

-

Branded Merchandise: Design and sell branded merchandise like tumblers, phone grips, or laptop skins for businesses or organizations.

-

Themed Collections: Create themed collections for holidays, seasons, or special events, offering a variety of customized products.

-

Niche Products: Cater to specific interests or hobbies with niche products like personalized pet bowls or sports-themed items.

-

Customizable Items: Offer customers the option to personalize items with names, initials, or photos.

Enhanced Crafts: Add a Professional Touch to Various Craft Projects

-

Scrapbooking and Card Making: Use UV DTF wraps to add personalized embellishments to scrapbooks, cards, and other paper crafts.

-

Woodworking and Furniture Refurbishing: Enhance woodworking projects or furniture refurbishing projects with custom designs or patterns.

-

Ceramics and Glassware: Add unique designs to ceramics, glassware, or other decorative items.

-

Fabric and Leather Crafts: Use UV DTF wraps to add personalized touches to fabric or leather crafts.

Creative Expression: Explore New Design Possibilities and Artistic Styles

-

Intricate Designs and Patterns: Create intricate designs and patterns that would be difficult to achieve with other methods.

-

Full-Color Photos and Gradients: Reproduce high-quality photos and gradients with vibrant colors and smooth transitions.

-

Original Artwork and Illustrations: Bring your original artwork and illustrations to life with UV DTF wraps.

-

Experiment with Different Themes and Styles: Explore various themes and styles, from abstract art to realistic illustrations.

Brand Building: Offer High-Quality, Personalized Products to Attract Customers

-

Consistent Quality and Professional Finish: Offer high-quality, professional-looking products that reflect your brand's image.

-

Unique and Memorable Designs: Create unique and memorable designs that set your products apart from the competition.

-

Personalized Customer Experience: Offer a personalized customer experience by providing customization options and excellent customer service.

-

Build a Loyal Customer Base: Attract and retain loyal customers by offering high-quality, personalized products that meet their needs and exceed their expectations.

How to make UV DTF Wrap?

1. Design Creation:

-

Conceptualize Your Design: Start by brainstorming your design ideas. Consider the intended application, the desired aesthetic, and the target audience. Sketch out your ideas or use digital design tools to create initial concepts.

-

Choose Your Software: Select a suitable graphic design software such as Adobe Illustrator or Photoshop. These programs offer a wide range of tools and features for creating professional-quality designs.

-

Design Development: Develop your design, paying attention to details such as line weight, color combinations, and overall composition. Ensure your design is vector-based for optimal printing resolution and scalability.

-

Prepare for Printing: Export your design in the appropriate file format (e.g., EPS, AI, PDF) and size for your DTF printer. Consider the dimensions and resolution of your printer to ensure optimal print quality.

-

Printing: Print the design onto UV DTF film using a UV printer.

-

Powder Application: Apply an adhesive powder to the printed design.

-

Curing: Cure the powder using a UV curing lamp or heat press.

-

Application: The wrap is now ready for application to the desired surface.

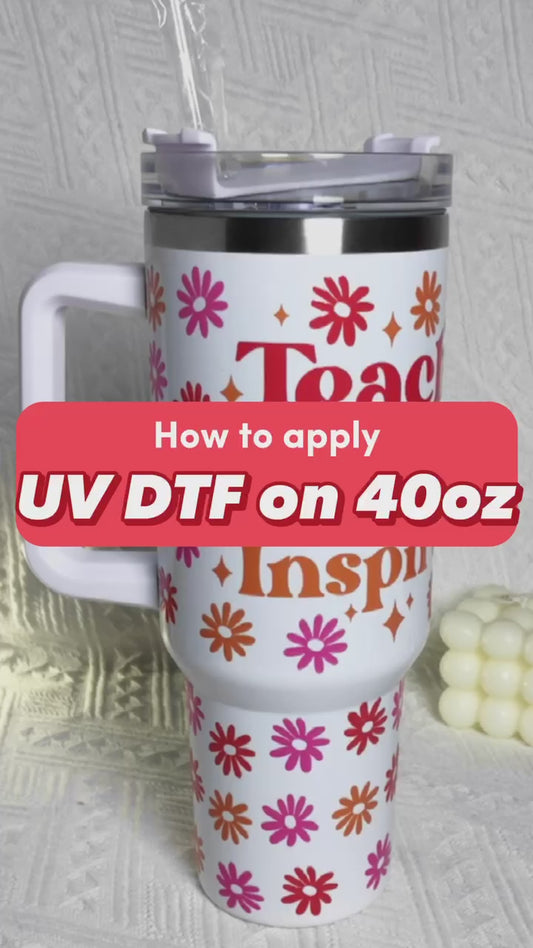

How to apply UV DTF Wrap to cups?

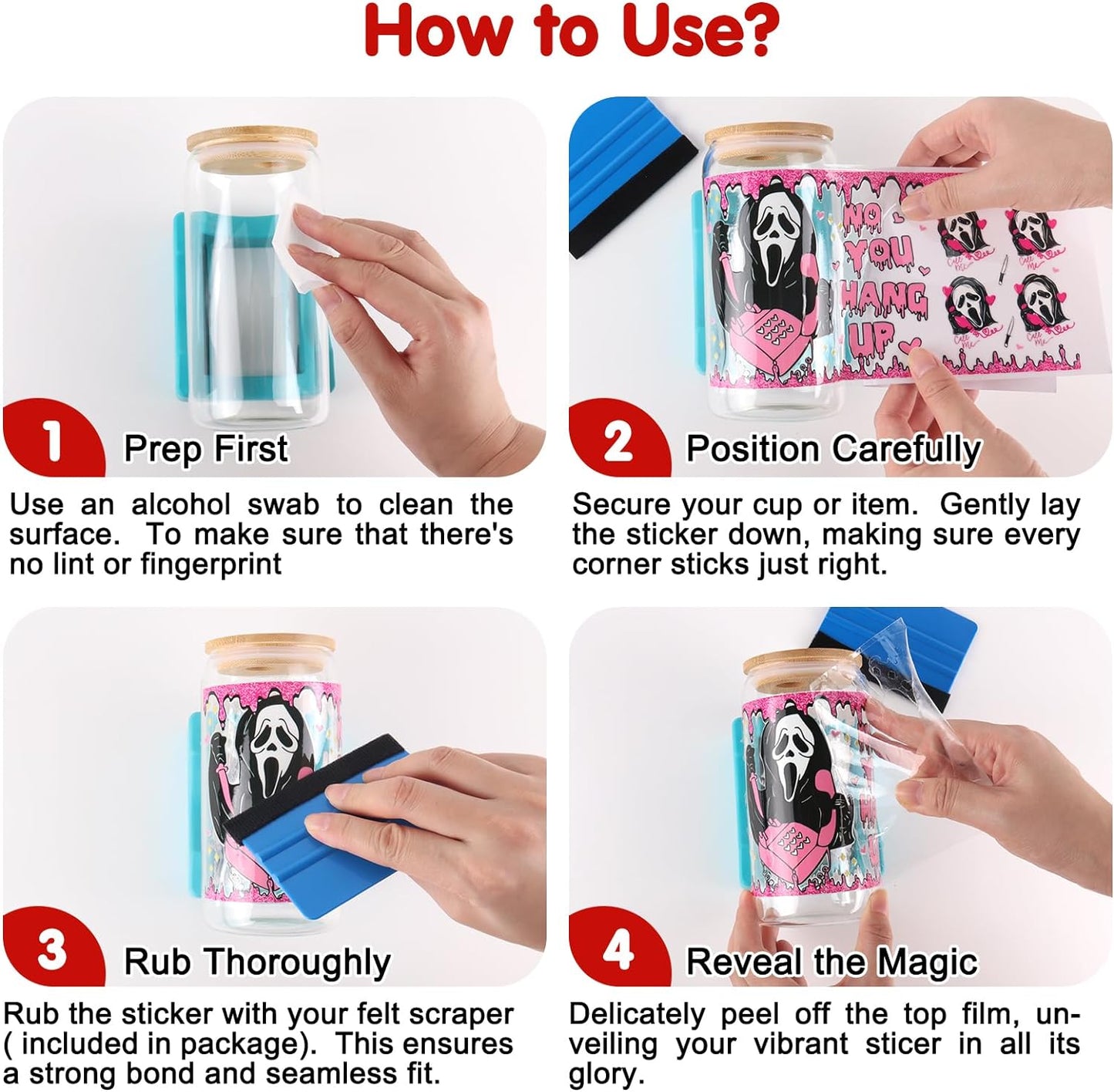

1. Preparing the Surface:

-

Clean the Cup Thoroughly: Ensure the cup's surface is free from dust, dirt, oils, and any other contaminants. Use isopropyl alcohol and a lint-free cloth for optimal cleaning.

-

Dry the Cup Completely: Allow the cup to air dry or use a clean, dry cloth to ensure no moisture remains on the surface. Moisture can interfere with the adhesive and prevent the wrap from adhering properly.

2. Applying the UV DTF Wrap:

-

Peel the Backing Carefully: Gently peel the backing paper from the UV DTF wrap, exposing the adhesive side. Handle the wrap by the edges to avoid touching the adhesive with your fingers, as this can transfer oils and reduce adhesion.

-

Position the Wrap Precisely: Align the wrap with the desired location on the cup. Start by aligning one edge and gently press it down, ensuring it's straight and centered.

-

Smooth the Wrap Evenly: Use a squeegee or your fingers to smooth out any air bubbles or wrinkles. Start from the center and work outwards, applying even pressure to ensure a smooth, seamless application.

3. Finalizing the Application:

-

Remove the Transfer Film: Carefully peel off the clear transfer film, leaving the design adhered to the cup. Do this slowly and at a sharp angle to prevent lifting the design.

-

Check for Adhesion: Inspect the wrap for any areas that may not be fully adhered. If necessary, gently press and smooth any lifted areas.

-

Allow to Set: Allow the wrap to set for a few minutes to ensure a strong bond before using the cup.

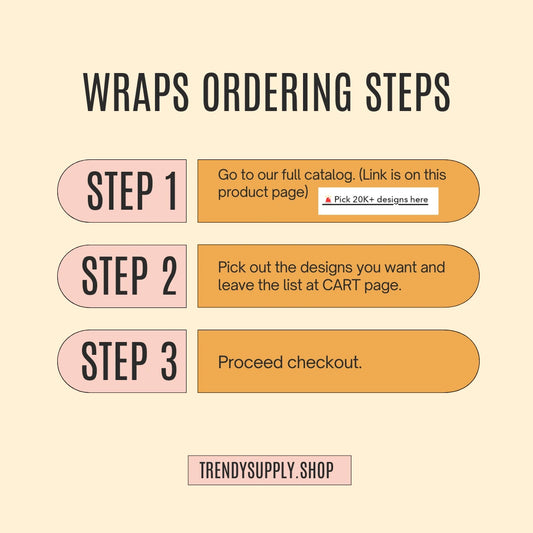

How to order wholesale UV DTF Wrap? Step by step

Pick out the designs you want:

-

Browse the supplier's catalog and select your designs.

Place the order on our website:

-

Add designs to your cart and proceed to checkout.

Printing and fast shipping:

-

The supplier will print and ship your order.

Frequently asked questions about UV DTF Wrap

Are UV DTF wraps dishwasher safe?

-

Check with the supplier for specific care instructions.

What surfaces can I apply UV DTF wraps to?

-

Smooth, non-porous surfaces are ideal.

Can I create my own designs?

-

Yes, with a UV printer, you can print custom designs.

How long do UV DTF wraps last?

-

With proper care, they can last for an extended period.

Master the Art of UV DTF Wrap Application: Elevate Your Custom Creations!

Achieving professional-looking results with UV DTF wraps is within your reach. With the right techniques and a little practice, you can create stunning, personalized items that will impress.

Ready to start applying UV DTF wraps like a pro? Explore our UV DTF wraps and begin your customization journey today!