UV DTF cup wraps printers are revolutionizing the way we personalized drinkware, tapping into a global market for custom drinkware valued at $35.1 billion in 2024 and is projected to reach $60.4 billion by 2034, according to a recent report. This surge in demand underscores the growing desire for unique, personalized items. These innovative machines empower individuals and businesses to create vibrant, durable, and custom cup wraps with ease. This guide will walk you through everything you need to know about UV DTF cup wraps printers, from understanding their technology to leveraging their potential for your crafting or business endeavors.

What is a UV DTF Cup Wraps Printer?

A UV DTF cup wraps printer is a specialized digital printer that utilizes Ultraviolet Direct-to-Film (UV DTF) technology. This technology involves printing designs onto a special film using UV-curable ink. The printed film, once cured, can then be transferred onto various smooth surfaces, including cups, tumblers, and other drinkware. These printers are designed to produce high-quality, durable, and vibrant wraps that adhere seamlessly to curved surfaces, making them ideal for customizing cups.

Why is UV DTF Cup Wraps Printer so popular?

Customization: Endless Design Possibilities

UV DTF printers allow for the creation of highly customized designs, including intricate graphics, full-color photos, and personalized text. This opens up a world of creative possibilities for crafting unique and eye-catching cup wraps.

Durability: Long-Lasting Results

The UV-cured ink creates a tough, scratch-resistant finish that can withstand daily use and washing. This ensures that your custom cup wraps maintain their vibrant colors and sharp details for an extended period.

Versatility: Wide Range of Applications

UV DTF printers can be used to create wraps for various types of cups and tumblers, including those made from glass, metal, plastic, and ceramic. This versatility makes them suitable for a wide range of customization projects.

Efficiency: Streamlined Production

The printing and curing process is relatively fast and efficient, allowing for quick turnaround times. This makes UV DTF printers ideal for both small-scale and large-scale production.

Professional Finish: High-Quality Output

UV DTF printers produce high-resolution prints with vibrant colors and sharp details, resulting in a professional-looking finish. This enhances the overall appearance of your customized cups.

How can crafters benefit from UV DTF Cup Wraps Printer?

Personalized Gifts and Products

Create unique and personalized gifts for friends, family, and customers. Imagine designing custom tumblers for a bridal shower, each adorned with the bride's name and a special message. Or, create personalized mugs for a sports team, featuring their logo and each player's name. These thoughtful gifts will be cherished by the recipients, showcasing your creativity and attention to detail.

Small Business Opportunities

Start a small business selling customized cups and tumblers with unique designs. Leverage online platforms, such as Etsy or social media marketplaces, to reach a wider audience. Consider offering bulk discounts for corporate gifts or event favors. Partner with local businesses or organizations to provide customized drinkware for their events or promotions. This entrepreneurial approach can lead to a successful and fulfilling business venture.

Creative Expression

Express your creativity by designing and printing your own custom cup wraps. Experiment with different themes, color palettes, and design elements to create truly unique and eye-catching pieces. Explore various artistic styles, from abstract art to realistic illustrations, and let your imagination run wild. This creative freedom will allow you to develop a distinctive style and stand out from the competition.

Enhanced Craft Projects

Add a professional touch to your craft projects by incorporating UV DTF wraps. Enhance handmade gifts, such as gift baskets or personalized stationery sets, with custom-designed cups. Create themed sets for holidays or special occasions, adding a personal touch to your creations. These thoughtful additions will elevate your craft projects and make them even more special.

Control Over Production

Having your own printer allows for full control over the design and production process, reducing reliance on external suppliers. This autonomy empowers you to manage your inventory, meet deadlines, and respond quickly to customer demands. You can also experiment with different designs and materials without incurring additional costs or delays.

Popular UV DTF Cup Wraps Printer

The L1800 UV DTF Printer

This modified Epson L1800 printer is a popular choice for small businesses and hobbyists. It offers high-resolution prints, vibrant colors, and compatibility with various DTF films. Its relatively compact size and affordable price point make it a great entry-level option.

The XP600 UV DTF Printer

Featuring the XP600 printhead, this printer is known for its fast printing speeds and excellent print quality. It's suitable for both small and medium-sized businesses and offers a balance of performance and affordability.

The A3 UV DTF Printer

If you require a larger print area, an A3 UV DTF printer might be the ideal choice. These printers can accommodate larger designs and are suitable for businesses that produce a high volume of customized products.

The Mutoh ValueJet 426UF

For those looking for a professional grade machine, the Mutoh ValueJet 426UF offers exceptional print quality, reliability, and precision. This printer is ideal for businesses that require high-volume production and consistent results.

How to print UV DTF wraps?

1. Design Creation:

-

Start by creating your desired design using graphic design software such as Adobe Illustrator or Photoshop.

-

Ensure your design is high-resolution and optimized for printing to achieve the best possible results. Consider factors like color accuracy, image sharpness, and the overall aesthetic of your design.

-

Plan for the specific dimensions of your cup to ensure the design is properly scaled and proportioned.

2. Print Setup:

-

Load the specialized DTF film into a dedicated UV printer. This film acts as the canvas for your design.

-

Adjust the print settings on your printer, including color profiles, print quality, and media type.

-

Ensure your printer is properly calibrated to achieve accurate color reproduction.

3. Printing:

-

Use high-quality UV-curable inks designed specifically for DTF printing. These inks are formulated to interact perfectly with the subsequent steps in the process, ensuring vibrant and long-lasting results.

-

Print your design onto the matte side of the DTF film with precision and accuracy. This step is crucial for achieving a high-quality, professional-looking transfer.

4. Curing:

-

Cure the ink using a UV curing lamp or the printer's built-in curing system.

-

Follow the manufacturer's instructions regarding curing time and intensity to ensure the ink is fully cured.

-

Proper curing is essential for achieving a durable and scratch-resistant finish.

5. Adhesive Application:

-

Apply a heat-activated adhesive powder evenly over the cured ink. This powder will act as the bonding agent between the design and the cup surface.

-

Ensure all areas of the design are covered with powder, but avoid applying too much, as this can lead to clumping or uneven adhesion.

-

Gently shake off any excess powder to prevent it from interfering with the subsequent steps in the process.

6. Heat Press:

-

Use a heat press to melt the adhesive powder and create a flexible adhesive layer.

-

Follow the manufacturer's instructions regarding temperature and time settings to ensure the powder is properly melted and fused.

-

This step is crucial for creating a strong and durable bond between the design and the cup surface.

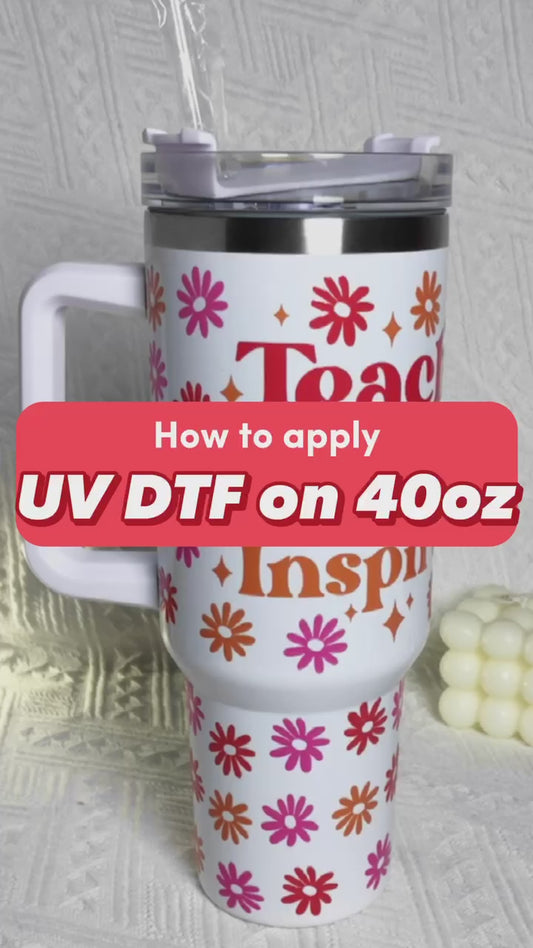

How to apply UV DTF Wraps to cups?

1. Preparing the Surface:

-

Clean the Cup Thoroughly: Ensure the cup's surface is free from dust, dirt, oils, and any other contaminants. Use isopropyl alcohol and a lint-free cloth for optimal cleaning.

-

Dry the Cup Completely: Allow the cup to air dry or use a clean, dry cloth to ensure no moisture remains on the surface. Moisture can interfere with the adhesive and prevent the wrap from adhering properly.

2. Applying the UV DTF Wrap:

-

Peel the Backing Carefully: Gently peel the backing paper from the UV DTF wrap, exposing the adhesive side. Avoid touching the adhesive with your fingers, as this can transfer oils and reduce adhesion.

-

Position the Wrap Precisely: Carefully align the wrap with the desired location on the cup. Start by aligning one edge and gently press it down, ensuring it's straight and centered.

-

Smooth the Wrap Evenly: Use a squeegee or your fingers to smooth out any air bubbles or wrinkles. Start from the center and work outwards, applying even pressure to ensure a smooth, seamless application.

3. Finalizing the Application:

-

Remove the Transfer Film Slowly: Carefully peel off the clear transfer film, leaving the design adhered to the cup. Do this slowly and at a sharp angle to prevent lifting the design.

-

Check for Adhesion: Inspect the wrap for any areas that may not be fully adhered. If necessary, gently press and smooth any lifted areas.

-

Allow to Set: Allow the wrap to set for a few minutes to ensure a strong bond before using the cup.

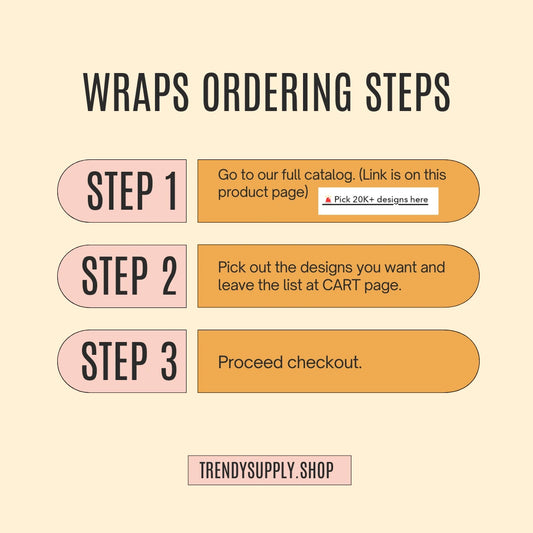

How to order wholesale UV DTF Cup Wraps? Step by step

Ordering wholesale UV DTF cup wraps can be a cost-effective way to stock up on supplies for your crafting or business needs. Here's a step-by-step guide:

Pick out the designs you want

-

Browse the Supplier's Catalog: Explore the online or physical catalog of your chosen wholesale supplier. Look for designs that align with your target market, style preferences, and product offerings.

-

Consider Design Variety: Select a diverse range of designs to appeal to a broader customer base. Include popular themes, trending patterns, and customizable options.

-

Evaluate Design Quality: Pay attention to the clarity, color vibrancy, and overall quality of the designs. Ensure they meet your standards for professional-looking products.

Place the order on our website

-

Add Items to Your Cart: Once you've selected your desired designs and quantities, add them to your online shopping cart.

-

Provide Shipping Information: Enter your accurate shipping address and contact details. Double-check for any errors to avoid delivery issues.

-

Choose Payment Method: Select your preferred payment method from the available options. Most suppliers accept major credit cards, PayPal, and bank transfers.

-

Review Your Order: Before submitting your order, carefully review all the details, including the items, quantities, shipping address, and payment information.

-

Submit Your Order: Once you're satisfied with your order, submit it and await confirmation from the supplier.

Printing and fast shipping

-

Order Processing: The supplier will process your order and prepare the selected designs for printing.

-

Printing and Curing: The designs will be printed onto DTF film using a UV printer and then cured to ensure durability and vibrancy.

-

Quality Control: The printed wraps will undergo quality control checks to ensure they meet the supplier's standards.

-

Packaging and Shipping: The wraps will be carefully packaged to prevent damage during transit and shipped to your specified address.

-

Tracking Information: You'll receive tracking information to monitor the progress of your shipment and estimate the delivery date.

Frequently asked questions about UV DTF Cup Wraps Printer

What types of cups can I use with UV DTF wraps?

UV DTF wraps adhere best to smooth, non-porous surfaces like glass, metal, plastic, and ceramic.

Are UV DTF wraps dishwasher safe?

While many UV DTF wraps are designed to be durable and water-resistant, it's always best to check with the specific supplier for their recommended care instructions. Some suppliers may recommend handwashing to extend the lifespan of the wraps.

Can I create my own designs?

Yes, if you have a UV DTF printer, you can create and print your own custom designs.

How long do UV DTF wraps last?

The lifespan of UV DTF wraps depends on factors such as usage, care, and exposure to environmental conditions. With proper care, they can last for an extended period.

What are the maintenance requirements for a UV DTF printer?

Regular maintenance is essential to keep your UV DTF printer in optimal condition. This includes cleaning the printhead, maintaining proper ink levels, and following the manufacturer's recommended maintenance schedule.

Craft Your Custom Cup Creations: Unleash Your Potential with a UV DTF Printer!

A UV DTF cup wraps printer empowers you to create unique, personalized, and professional-looking cup wraps from the comfort of your own space. Whether you're a crafter, small business owner, or entrepreneur, this technology offers endless possibilities for customization and creativity.

Ready to start creating your own custom cup wraps? Explore our UV DTF cup wraps and start customizing today!