Applying UV DTF cup wraps are revolutionizing personalized drinkware! This comprehensive guide will walk you through everything you need to know, from understanding what they are to mastering the application process. With the personalized gift market booming and an estimated annual growth rate of 8%, now is the perfect time to unleash your creativity and discover why crafters everywhere are raving about this innovative technique. Get ready to transform ordinary cups into stunning, personalized masterpieces!

What are UV DTF Cup Wraps?

UV DTF cup wraps are essentially designs printed onto a special film using UV (ultraviolet) technology. This process creates highly durable, vibrant, and detailed images. These designs are then transferred directly onto the surface of a cup (or other objects) without the need for heat pressing. Think of them as super-stickers, but with professional-grade quality and longevity. They offer a fantastic way to personalize and customize drinkware with eye-catching graphics.

Why are UV DTF Cup Wraps so Popular?

UV DTF cup wraps have quickly become a favorite among crafters and small business owners due to their numerous advantages:

Vibrant, Long-Lasting Designs

UV printing produces rich, vivid colors that resist fading, scratching, and water damage.

Easy Application

Unlike other methods like sublimation, UV DTF wraps don't require heat or specialized equipment. This makes them incredibly user-friendly.

Versatility

They can be applied to a wide range of surfaces, including glass, plastic, and metal. This opens up a world of customization possibilities beyond just cups.

No Weeding

Compared to vinyl, UV DTF transfers eliminate the tedious process of "weeding" away excess material.

Durability

The finished product is very durable and can withstand regular use.

How Can Crafters Benefit from UV DTF Cup Wraps?

UV DTF cup wraps offer several benefits for crafters:

Increased Creativity

Crafters can bring their most intricate and colorful designs to life on a variety of surfaces.

Time-Saving

The easy application process significantly reduces production time compared to other methods.

Professional Results

UV DTF wraps provide a high-quality, professional finish that enhances the value of their creations.

Business Opportunities

Crafters can expand their product offerings and create unique, personalized items to sell.

Reduced Waste

The no-weeding process minimizes material waste.

How to Make UV DTF Cup Wraps?

While you can create designs, the actual printing of UV DTF wraps requires specialized equipment. Most crafters and small businesses find it most efficient to order pre-printed wraps from a supplier. The process involves:

Design Creation

Creating a digital design using graphic design software. This stage involves using software like Adobe Illustrator, Photoshop, or CorelDRAW to create the desired image. Factors like image resolution, color accuracy, and design size are crucial for a high-quality final product.

Printing

The design is printed onto a special film using a UV printer. UV printers use ultraviolet light to cure the ink as it's printed, resulting in a durable, vibrant image. The type of UV printer and ink used can affect the final quality and durability of the wrap.

Lamination

A film is applied to the design. This lamination process adds a protective layer over the printed design, enhancing its resistance to scratches, abrasion, and other forms of wear and tear. It also contributes to the overall look and feel of the final product.

Transfer

The design is then transferred from the film to the cup. This involves carefully applying the printed and laminated film to the cup surface, ensuring proper alignment and adhesion. Techniques like using a squeegee to remove air bubbles and ensure a smooth application are often employed.

Applying UV DTF Cup Wraps: Step-by-Step Guide

Applying UV DTF wraps is a straightforward process. Here's a more detailed, step-by-step guide to ensure optimal results:

1. Prepare Your Cup

-

Clean Thoroughly: Ensure the cup is clean, dry, and free of any dust, oils, or debris. Any residue can interfere with the wrap's adhesion.

-

Use Isopropyl Alcohol: Isopropyl alcohol (70% or higher) is ideal for cleaning. Apply it to a lint-free cloth and wipe the cup's surface.

-

Dry Completely: Allow the alcohol to fully evaporate before proceeding. This is crucial, as any moisture can affect the application.

2. Position the Wrap

-

Accurate Alignment: Carefully align the UV DTF wrap around the cup. Proper alignment is essential for a professional-looking result.

-

Consider Cup Shape: For tapered cups, you may need to apply the wrap in sections or use a flexible wrap to ensure a smooth fit.

-

Gentle Handling: Handle the wrap gently to avoid stretching or creasing it.

3. Adhere the Wrap

-

Start from the Center: Press the wrap firmly onto the cup, starting from the center and working outwards. This helps to prevent air bubbles.

-

Smooth Out Bubbles: Use your fingers or a squeegee to smooth out any bubbles or wrinkles. Apply even pressure to ensure good adhesion.

-

Squeegee Technique: If using a squeegee, hold it at a slight angle and use firm, even strokes. A soft cloth over the squeegee can prevent scratching.

4. Remove the Film

-

Peel Slowly: Gently peel off the clear transfer film, leaving the design adhered to the cup.

-

Check for Adhesion: Peel slowly and carefully, checking that the design is fully adhered to the cup as you go. If any part of the design lifts, stop peeling and press that area down again before continuing.

-

Avoid Stretching: Be careful not to stretch the wrap while peeling the film, as this can distort the design.

5. Cure Time

-

Allow to Cure: Wait 24-48 hours before washing or heavy use. This allows the adhesive to fully bond with the cup surface, ensuring maximum durability.

-

Handle with Care: During the curing process, handle the cup with care to avoid accidentally damaging the wrap.

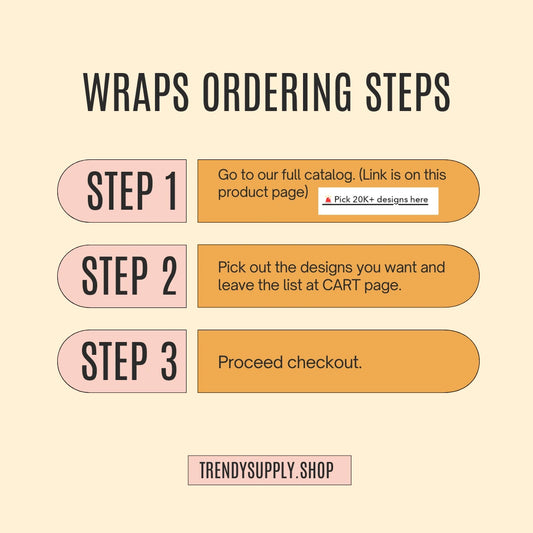

How to Order UV DTF Cup Wraps? Step-by-Step

Ordering UV DTF cup wraps is easy. Here's a general process:

Pick Out the Designs You Want

Browse a website or catalog to select from a variety of existing designs, or upload your own custom designs.

Place the Order on Our Website

Add your chosen designs and the desired quantity to your cart and proceed to checkout.

Printing and Fast Shipping

Your designs will be professionally printed using UV DTF technology, and shipped to you quickly and efficiently.

Frequently Asked Questions About Applying UV DTF Cup Wraps

Can UV DTF wraps be removed?

While very durable, they can be removed with some effort and the use of adhesive removers, but they are designed to be permanent.

Are UV DTF wraps dishwasher and microwave safe?

It's generally recommended to hand wash items with UV DTF wraps to prolong their lifespan. They are not typically microwave-safe.

What surfaces can UV DTF wraps be applied to?

They adhere best to smooth, hard surfaces like glass, metal, and certain plastics.

Do I need any special equipment?

No special equipment is needed for application, but a squeegee can be helpful.

Level Up Your Cup Game!

UV DTF cup wraps offer a game-changing way to personalize drinkware and other items. With their vibrant colors, durability, and ease of application, they're a must-have for crafters and businesses alike.

Ready to get started? Explore our wide selection of UV DTF cup wraps and unleash your creativity today!