Designer UV DTF wraps are transforming the world of customization, offering an effortless way to add high-end, intricate designs to almost any hard surface, bringing a touch of luxury to everyday items. With the global personalized gifts market estimated to grow by USD 10.76 billion from 2025-2029, the demand for unique, premium-looking customized products is significant, and these wraps provide the perfect tool for crafters and individuals to create such items with ease.

What are Designer UV DTF Wraps?

Understanding UV DTF Technology

UV DTF (Ultraviolet Direct to Film) is an advanced printing method that involves printing a design using special UV-curable inks onto a release liner. An adhesive and a transfer film are then applied, creating a durable, flexible decal. When exposed to UV light during the printing process, the ink cures instantly, resulting in a robust and vibrant transfer.

High-End Designs, Easy Application

Designer UV DTF wraps take this technology a step further by featuring sophisticated, often intricate, or luxurious designs. These are not just simple graphics but patterns, textures, or artistic elements that mimic high-end finishes or styles. They are essentially peel-and-stick transfers that allow you to apply these complex designs onto smooth, hard items like tumblers, glass, metal, and plastic with simple pressure, no heat required.

Why are Designer UV DTF Wraps so popular?

Achieve a Luxury Look Instantly

One of the main reasons for their popularity is the ability to achieve a high-end, designer look without the cost or complexity typically associated with luxury customization methods. These wraps offer intricate details, vibrant colors, and often tactile finishes that elevate the appearance of ordinary items.

Effortless and Fast Application

The simplicity of application is a major draw. The peel-and-stick nature means you can transform an item in minutes, saving significant time compared to painting, intricate stenciling, or other detailed customization techniques. This makes achieving a polished look accessible to everyone.

Durable and Long-Lasting

Despite their easy application, Designer UV DTF wraps are remarkably durable. Once applied, they are waterproof, scratch-resistant, and resistant to fading, ensuring your customized items maintain their luxurious appearance even with regular use and washing.

Versatility for Various Items

While popular for drinkware, Designer UV DTF wraps can be applied to a wide range of hard, smooth surfaces, including laptops, phone cases, notebooks, storage containers, home decor items, and more, allowing you to add a touch of designer flair to almost anything.

How can crafters benefit from Designer UV DTF Wraps?

Elevate Product Offerings

Crafters can significantly enhance the perceived value and appeal of their products by incorporating designer-quality finishes using these wraps. This allows them to cater to a market segment looking for more sophisticated and luxurious handmade items.

Increase Production Efficiency

The rapid application process of UV DTF wraps allows crafters to increase their production speed and output. This is particularly beneficial for fulfilling larger orders or creating inventory quickly for markets and online shops.

Reduce Material Waste and Complexity

Compared to methods like intricate vinyl cutting, UV DTF wraps produce minimal waste. They also simplify the process of applying complex, multi-color designs that would be challenging or time-consuming with other techniques.

Tap into the Luxury DIY Trend

Designer UV DTF wraps allow crafters to capitalize on the growing trend of DIY luxury and personalized high-end goods, attracting customers who desire unique items with a premium aesthetic.

How to apply Designer UV DTF Wraps?

Applying your Designer UV DTF wrap is a straightforward process for achieving a flawless finish:

1. Prepare Your Surface

Ensure the surface of your item is perfectly clean, dry, and free from any dust, oils, or fingerprints. Cleaning with isopropyl alcohol and allowing it to dry completely is highly recommended for optimal adhesion.

2. Carefully Peel the Backing

Peel the white backing paper away from the clear transfer film. Be careful to ensure the entire design remains adhered smoothly to the clear film.

3. Position the Design Accurately

Gently place the clear transfer film with the design onto your item. Take your time to align it perfectly, as the adhesive is strong, and repositioning after contact is difficult.

4. Rub Firmly to Adhere

Once the wrap is in position, use your fingers or a squeegee to firmly rub over the entire design. Apply strong, even pressure across all areas to ensure the adhesive bonds completely to the surface, working out any air bubbles as you go.

5. Slowly Remove the Transfer Film

Carefully and slowly peel back the clear transfer film at an angle. If any part of the design lifts, lay the film back down and rub over that area again before continuing to peel the film off completely.

6. Final Press and Cure

After the film is removed, rub the design firmly one last time to ensure maximum adhesion. For best durability, allow the wrap to cure for 24-48 hours before exposing it to washing or heavy use.

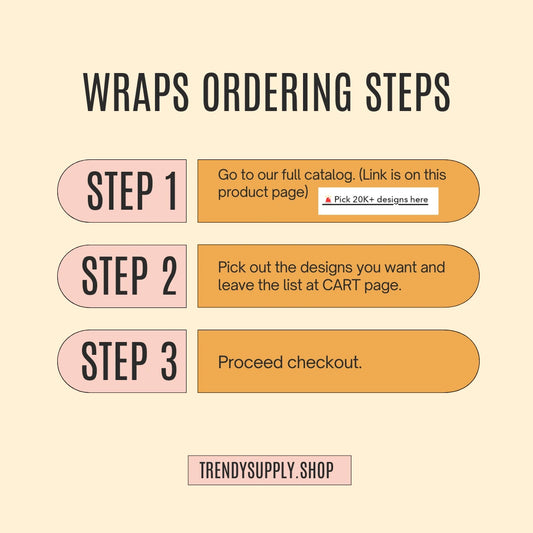

How to order wholesale Designer UV DTF Wraps? Step by step

Ordering wholesale Designer UV DTF wraps for your crafting business or resale is designed to be simple and efficient:

Pick out the designs you want

Browse our exclusive wholesale catalog of Designer UV DTF wrap designs. We offer a wide selection of sophisticated patterns, textures, and artistic graphics perfect for creating high-end customized products. Select the designs and quantities that best suit your business needs and add them to your wholesale cart.

Place the order on our website

Proceed to our dedicated wholesale checkout page. Enter your business and shipping information. Review your order details and apply any wholesale account discounts. Complete your purchase through our secure payment gateway.

Printing and fast shipping

Once your wholesale order is confirmed, our production team will prioritize printing your chosen Designer UV DTF wraps using our high-volume UV DTF printers. We meticulously package wholesale orders to ensure they arrive in perfect condition and arrange for fast shipping to get your inventory to you promptly.

Frequently asked questions about applying Designer UV DTF Wraps

Are Designer UV DTF wraps durable for everyday use?

Yes, absolutely. Once properly applied and cured, they are highly durable, waterproof, and resistant to scratches and fading, making them suitable for items used daily like cups and phone cases.

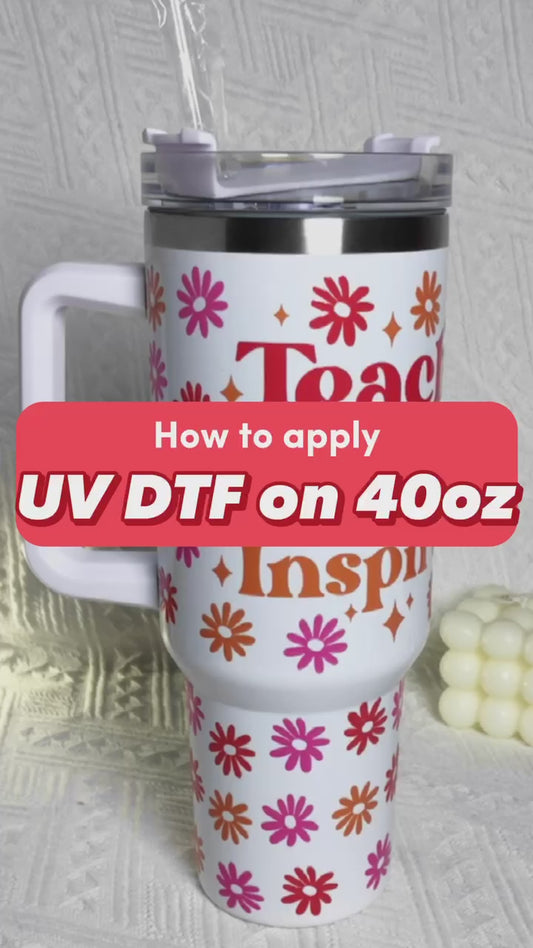

Can I apply these wraps to curved surfaces like tumblers?

Yes, they are flexible and designed to conform to curved surfaces. Patience and careful rubbing during application are key to achieving a smooth, bubble-free finish on curves.

Do I need any special equipment to apply them?

No, the beauty of UV DTF wraps is that they only require pressure for application. You can use your fingers or a simple squeegee tool. No heat press or other machinery is needed.

Can these wraps be removed or repositioned?

Once the adhesive makes firm contact with the surface and is rubbed down, the bond is strong and intended to be permanent. Attempting to remove or reposition the wrap will likely damage the design or the surface.

How long does the wrap need to cure?

While the ink is cured during printing, the adhesive needs time to fully bond to your item. We recommend a curing period of 24-48 hours before the first wash or heavy use for maximum durability.

Unlock Luxury Customization!

Designer UV DTF wraps are your secret weapon for adding a touch of luxury and sophistication to your DIY projects and product offerings. Their ease of use, combined with stunning, durable results, makes achieving a high-end look more accessible than ever before. Elevate your crafting, personalize your world, and create items that stand out with these innovative wraps.

Ready to add designer flair to your creations? Explore our collection of Designer UV DTF wraps and start crafting your luxury items today!