How to make UV DTF cup wraps is a question many crafters are asking, as the personalized drinkware market continues to surge. Did you know the global custom drinkware market was valued at $35.1 billion in 2024 and is projected to reach $14 billion by 2030, according to a report? This booming market underscores the strong demand for unique, personalized items. To capitalize on this trend, crafters and DIY enthusiasts are embracing innovative techniques like UV DTF (Ultraviolet Direct-to-Film) cup wraps. This guide will provide a clear, step-by-step walkthrough of how to create your own UV DTF cup wraps, enabling you to personalize your drinkware with professional-looking designs from the comfort of your home.

What are UV DTF Cup Wraps?

UV DTF (Ultraviolet Direct-to-Film) cup wraps are pre-printed decals that use UV-curable ink to create high-quality, long-lasting designs. These wraps are designed to adhere to smooth surfaces, particularly cups and tumblers, offering a vibrant and durable alternative to traditional stickers or vinyl decals. The UV curing process ensures the designs are resistant to scratches, fading, and water damage, making them perfect for everyday use.

Why are UV DTF Cup Wraps so popular?

Durability: Long-Lasting Designs

UV DTF wraps are highly durable and resistant to scratches, fading, and water damage, ensuring your designs stay vibrant for a long time.

Versatility: Customizable Applications

They can be applied to a variety of smooth surfaces, including glass, metal, and plastic, making them versatile for customizing different types of cups and tumblers.

Vibrant Colors: Eye-Catching Designs

The UV curing process produces vibrant, high-resolution colors that won't fade over time.

Ease of Application: Simple DIY Process

Applying UV DTF wraps is a relatively simple process, even for beginners.

Professional Finish: High-Quality Results

They provide a professional, polished finish that enhances the appearance of your cups.

How can crafters benefit from UV DTF Cup Wraps?

Personalized Gifts

Create unique and personalized gifts for friends, family, and customers. Imagine crafting a set of personalized mugs for a wedding, each adorned with the couple's initials and a heartfelt message. Or, design custom tumblers for a sports team, featuring their logo and each player's name. These thoughtful gifts will be cherished by the recipients, showcasing your creativity and attention to detail.

Custom Products

Expand your product line by offering customized cups and tumblers with unique designs. Cater to specific niches, such as book lovers with literary quotes, teachers with inspirational messages, or pet owners with adorable animal designs. Offer a variety of styles, from minimalist designs to intricate artwork, to appeal to a broad customer base. This diversification will attract new customers and boost your sales potential.

Creative Expression

Express your creativity by designing and applying your own custom designs to cups. Experiment with different themes, color palettes, and design elements to create truly unique and eye-catching pieces. Explore various artistic styles, from abstract art to realistic illustrations, and let your imagination run wild. This creative freedom will allow you to develop a distinctive style and stand out from the competition.

Small Business Opportunities

Start a small business selling customized cups and tumblers with UV DTF wraps. Leverage online platforms, such as Etsy or social media marketplaces, to reach a wider audience. Consider offering bulk discounts for corporate gifts or event favors. Partner with local businesses or organizations to provide customized drinkware for their events or promotions. This entrepreneurial approach can lead to a successful and fulfilling business venture.

Enhanced Craft Projects

Add a professional touch to your craft projects by incorporating UV DTF wraps. Enhance handmade gifts, such as gift baskets or personalized stationery sets, with custom-designed cups. Create themed sets for holidays or special occasions, adding a personal touch to your creations. These thoughtful additions will elevate your craft projects and make them even more special.

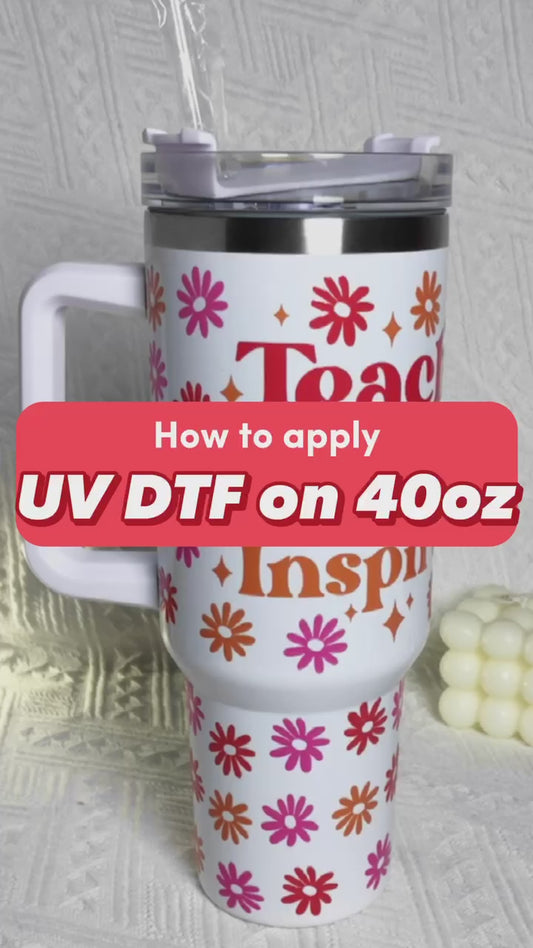

How to apply UV DTF Cup Wraps to cups?

Clean the Surface

Ensure the cup is clean and dry before applying the wrap.

Peel the Backing

Carefully peel off the backing from the UV DTF wrap, exposing the adhesive side.

Position the Wrap

Align the wrap on the cup and gently press it down, ensuring it's straight and centered.

Smooth the Wrap

Use a squeegee or your fingers to smooth out any air bubbles or wrinkles, working from the center outwards.

Remove the Transfer Film

Carefully peel off the clear transfer film, leaving the design adhered to the cup.

How to make UV DTF Cup Wraps

Making UV DTF cup wraps involves a multi-step process that combines digital printing technology with specialized materials:

1. Design Creation:

-

Start by creating your desired design using graphic design software such as Adobe Illustrator or Photoshop.

-

Ensure your design is high-resolution and optimized for printing to achieve the best possible results. Consider factors like color accuracy, image sharpness, and the overall aesthetic of your design.

-

Plan for the specific dimensions of your cup to ensure the design is properly scaled and proportioned.

2. Printing:

-

The heart of the DTF process lies in the printing stage. Load the specialized DTF film into a dedicated UV printer. This film acts as the canvas for your design.

-

Use high-quality UV-curable inks designed specifically for DTF printing. These inks are formulated to interact perfectly with the subsequent steps in the process, ensuring vibrant and long-lasting results.

-

Print your design onto the matte side of the DTF film with precision and accuracy. This step is crucial for achieving a high-quality, professional-looking transfer.

3. Powder Application:

-

Once the design is printed, a crucial step involves applying a heat-activated adhesive powder evenly over the wet ink. This powder is the secret ingredient that will enable the transfer to adhere securely to the cup.

-

Carefully distribute the powder, ensuring all areas of the printed design are adequately covered. Avoid applying too much powder, as this can lead to clumping or uneven adhesion.

-

Gently shake off any excess powder to prevent it from interfering with the subsequent steps in the process.

4. Powder Curing:

-

The next step is to cure the powder, transforming it from a loose powder into a flexible adhesive layer. This is typically achieved using a heat press or a dedicated powder curing oven.

-

Follow the specific instructions provided by the equipment manufacturer regarding temperature and time settings to ensure optimal curing results. This step is critical for the success of the transfer process as it solidifies the bond between the design and the adhesive.

5. Transfer Application:

-

Once the powder is cured, your UV DTF transfer is ready for application. This stage involves carefully positioning the transfer onto the desired location on the cup and applying heat and pressure to fuse the design to the cup's surface.

-

Use a squeegee or your fingers to smooth out any air bubbles or wrinkles, ensuring a seamless and professional finish.

-

Allow the transfer to cool completely before carefully peeling off the clear film backing.

Additional Tips:

-

Cleanliness is Key: Ensure your workspace and equipment are clean to prevent dust or debris from interfering with the transfer process.

-

Practice Makes Perfect: Experiment with different techniques and materials to refine your skills and achieve the best possible results.

-

Safety First: Wear appropriate safety gear, such as gloves and safety glasses, when working with UV inks and adhesives.

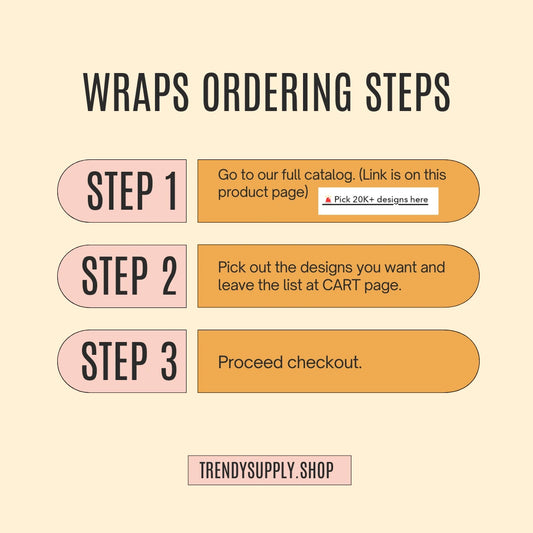

How to order wholesale UV DTF Cup Wraps? Step by step

Ordering wholesale UV DTF cup wraps can be a cost-effective way to stock up on supplies:

Pick out the designs you want

-

Browse the supplier's online catalog or request a physical catalog.

-

Select designs that align with your target market and product offerings.

Place the order on our website

-

Add the desired designs and quantities to your shopping cart.

-

Provide your shipping and payment information.

-

Double-check your order details before submitting.

Printing and fast shipping

-

The supplier will process your order and print the selected designs.

-

Your order will be shipped promptly to your specified address.

Frequently asked questions about UV DTF Cup Wraps

Are UV DTF cup wraps dishwasher safe?

Many are, but it's best to check with the specific supplier.

What types of cups can I use with UV DTF wraps?

Smooth, non-porous cups like glass, metal, and plastic are ideal.

Can I create my own designs?

Yes, if you have a UV printer, you can create and print your own designs.

How long do UV DTF cup wraps last?

With proper care, they can last for a long time.

Craft Your Custom Cups: Unleash Your Creativity with UV DTF Wraps!

UV DTF cup wraps offer a fun and easy way to personalize your drinkware. Whether you're a crafter, business owner, or simply someone who loves unique items, UV DTF wraps are a fantastic option.

Ready to start creating your own custom cups? Explore our uv dtf cup wraps here and begin your UV DTF journey today!