How to make UV DTF wraps?The demand for custom - printed items is on the rise, and UV DTF (Direct to Film) wraps have emerged as a popular solution among crafters and businesses alike. The Direct to Film Printing Market size was estimated at USD 2.56 billion in 2023, USD 2.72 billion in 2024, and is expected to reach USD 3.99 billion by 2030. This growth is largely driven by the increasing popularity of techniques like UV DTF wrapping, which offer high - quality, vibrant prints on a variety of surfaces. Whether you're a seasoned crafter looking to expand your skills or a business owner aiming to offer unique products, learning how to make UV DTF wraps can open up a world of creative and profitable opportunities.

What are UV DTF Wraps?

Definition and Basics

UV DTF wraps are a type of digital printing technology that involves printing designs onto a special film using UV - cured inks. The process starts with creating a digital design, which is then printed in reverse onto a PET (polyethylene terephthalate) film. After printing, a layer of adhesive is applied on top of the ink, followed by a layer of clear protective coating. The adhesive and coating are cured using UV light, creating a durable and flexible wrap that can be transferred onto various substrates such as cups, tumblers, phone cases, and more. The result is a high - resolution, full - color print with sharp details and vibrant colors that can withstand regular use and washing.

Key Components

-

Inks: UV - cured inks are the heart of the UV DTF process. These inks contain photoinitiators that react when exposed to UV light, causing the ink to dry and harden almost instantly. This rapid curing process ensures that the colors stay vivid and the print doesn't smudge or fade easily.

-

Film: The PET film serves as the base for the print. It has a smooth surface that allows for precise ink deposition and also provides a stable carrier for the design during the transfer process.

-

Adhesive and Coating: The adhesive layer is what allows the print to stick to the target surface, while the clear protective coating safeguards the print from scratches, moisture, and other environmental factors, enhancing the longevity of the wrap.

Why are UV DTF Wraps so popular?

High - Quality Prints

-

Vibrant Colors: UV DTF technology is capable of producing prints with incredibly vibrant and true - to - life colors. The use of UV - cured inks ensures that the colors remain bright and saturated, even on dark or non - porous surfaces. This makes UV DTF wraps ideal for creating eye - catching designs that stand out.

-

Sharp Details: Thanks to the high - resolution printing capabilities, UV DTF wraps can reproduce intricate details with great precision. Whether it's a detailed logo, a complex illustration, or fine text, the final print will look crisp and professional.

Versatility

-

Wide Range of Substrates: UV DTF wraps can be applied to a diverse range of substrates, from smooth surfaces like glass and metal to textured materials such as wood and fabric. This versatility makes it suitable for various applications, including customizing drinkware, promotional products, and personalized gifts.

-

Multiple Design Options: Crafters and designers have the freedom to create any design they can imagine, from simple monograms to elaborate multi - colored graphics. The digital nature of the process allows for easy customization and modification of designs, enabling businesses and individuals to offer unique, one - of - a - kind products.

Durability

The combination of the UV - cured inks, adhesive, and protective coating makes UV DTF wraps highly durable. They can resist fading, scratching, and peeling, even when exposed to harsh conditions like sunlight, water, and abrasion. This durability ensures that the wrapped products maintain their appearance over time, making them a reliable choice for both short - term and long - term use.

How can crafters benefit from UV DTF Wraps?

Creative Freedom

-

Unlimited Design Possibilities: Crafters are no longer restricted by traditional printing limitations. With UV DTF wraps, they can bring their most imaginative ideas to life, creating unique and personalized products that stand out in the market. Whether it's creating custom - designed jewelry, home decor items, or fashion accessories, the possibilities are endless.

-

Experimentation: The digital nature of UV DTF printing allows crafters to easily experiment with different colors, textures, and design elements. They can quickly test out new ideas, make adjustments, and refine their designs without the high costs and time - consuming processes associated with traditional printing methods.

Business Growth

-

Increased Product Offerings: By adding UV DTF - wrapped products to their inventory, crafters can expand their product line and attract a wider customer base. The ability to offer custom - printed items can set them apart from competitors and increase their sales potential.

-

Higher Profit Margins: Custom - made UV DTF - wrapped products often command higher prices compared to mass - produced items. Crafters can capitalize on this by charging premium prices for their unique, hand - crafted products, thus increasing their profit margins.

Time - and Cost - Efficiency

-

Faster Production: The UV DTF process is relatively quick, with the UV curing step reducing the drying time significantly. This means that crafters can produce more items in less time, improving their productivity and meeting customer demands more efficiently.

-

Reduced Material Waste: Since UV DTF printing is a digital process, it allows for precise ink deposition, minimizing material waste. Additionally, the ability to print on demand reduces the need for large - scale inventory storage, further saving costs.

How to Make UV DTF Wraps

Design Preparation

-

Create or Source a Design: Start by creating your own design using graphic design software like Adobe Photoshop or Illustrator. If you're not a designer, you can also source pre - made designs from online marketplaces or design communities. Make sure the design is in a high - resolution format (at least 300 DPI) to ensure a clear and sharp print.

-

Size and Formatting: Adjust the size of the design according to the dimensions of the substrate you'll be applying the wrap to. Also, ensure that the design is formatted correctly for the UV DTF printer, usually in a file format like PDF, JPEG, or PNG.

Printing

-

Load the Film: Place the PET film into the UV DTF printer according to the manufacturer's instructions. Make sure the film is properly aligned to ensure accurate printing.

-

Print the Design: Set the printer settings for UV DTF printing, including the ink density, print resolution, and UV curing settings. Send the design to the printer and let it print the design in reverse onto the film. The UV light will cure the inks as they are printed, ensuring a quick and durable print.

Applying Adhesive and Coating

-

Adhesive Application: After printing, use a specialized machine or tool to apply a layer of adhesive over the printed design on the film. Make sure the adhesive is evenly distributed to ensure proper bonding during the transfer process.

-

Coating Application: Following the adhesive, apply a clear protective coating over the adhesive layer. This coating will protect the print from damage and enhance its durability. Once again, cure the adhesive and coating using UV light.

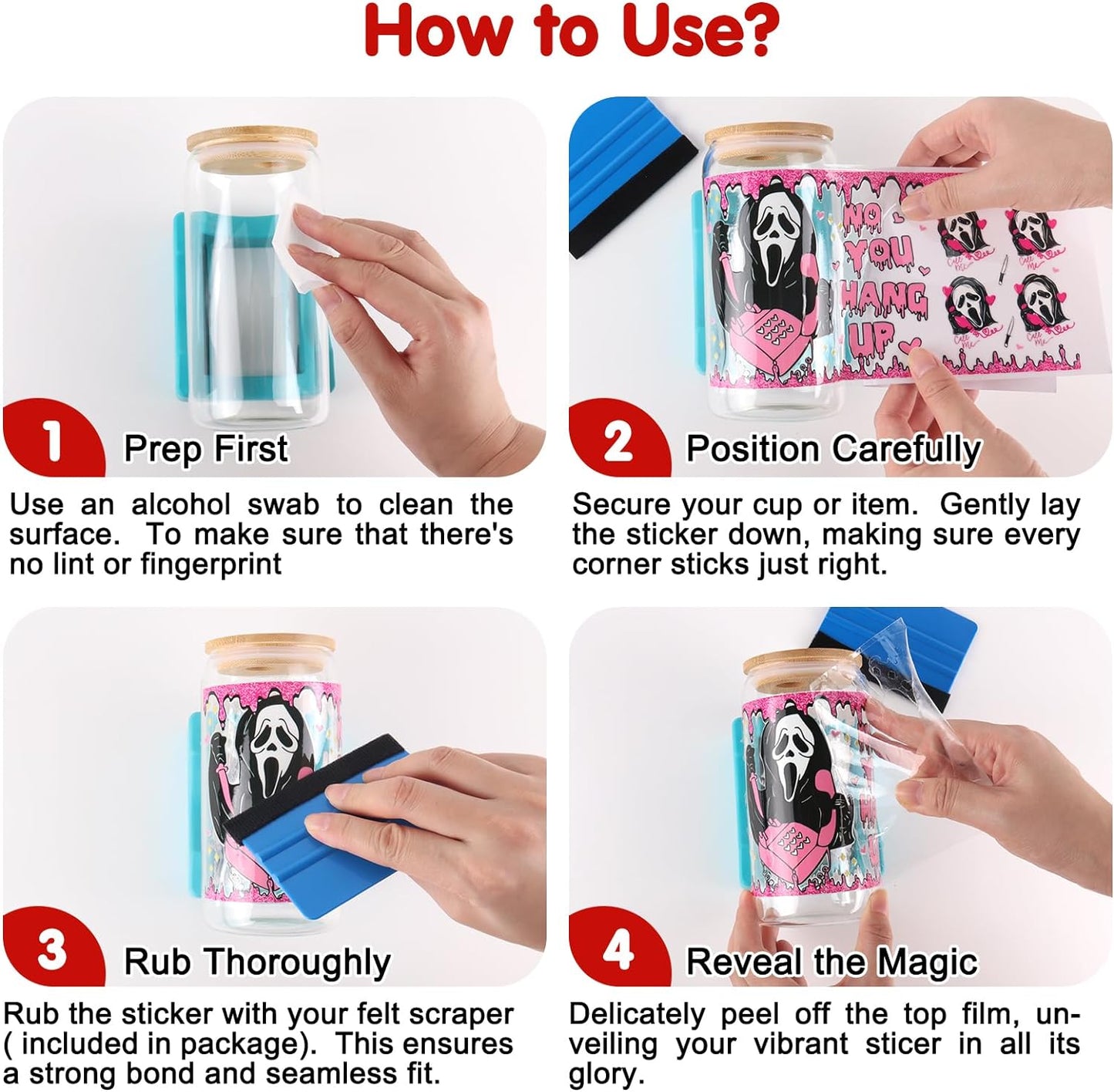

Transfer Process

-

Prepare the Substrate: Clean and prepare the substrate (e.g., cup, tumbler) by removing any dirt, oil, or debris. This will ensure a smooth and secure transfer of the wrap.

-

Transfer the Wrap: Carefully peel the printed and coated film from the backing and place it onto the substrate, starting from one end and slowly smoothing it out to remove any air bubbles. Use a heat press or a heat gun to apply heat and pressure, which will activate the adhesive and bond the wrap to the substrate. Once the wrap is firmly attached, peel off the film, leaving the design and adhesive on the substrate.

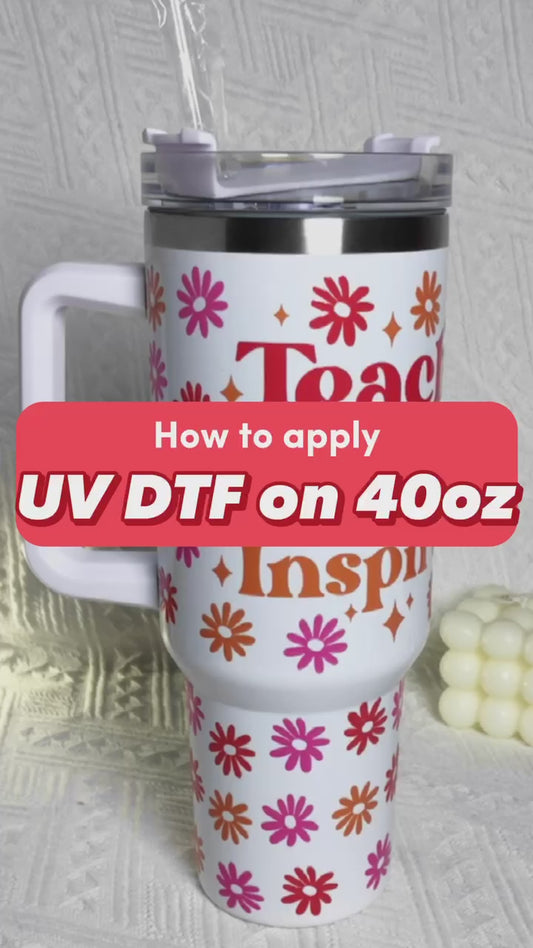

How to apply uv dtf wraps to cups?

Cup Preparation

-

Cleaning: Wash the cup thoroughly with warm soapy water and dry it completely. Any residue on the cup can prevent the wrap from adhering properly, so it's essential to ensure it's clean and dry.

-

Sanding (if necessary): For some cups with a smooth, glossy surface, lightly sanding the area where the wrap will be applied can help improve adhesion. Use fine - grit sandpaper and sand in a circular motion, then wipe away any dust with a clean cloth.

Wrap Application

-

Positioning: Carefully align the UV DTF wrap on the cup, starting from the top or bottom and working your way around. Use a squeegee or a credit card to smooth out the wrap as you go, removing any air bubbles. Make sure the wrap is straight and centered for a professional look.

-

Heat Application: Use a heat gun or a cup press to apply heat to the wrap. Move the heat source evenly around the cup, applying gentle pressure with the squeegee or your hands to ensure the wrap adheres firmly. The heat will activate the adhesive, bonding the wrap to the cup's surface.

-

Trimming (if needed): If there is any excess wrap extending beyond the edges of the cup, use a sharp pair of scissors or a craft knife to trim it neatly.

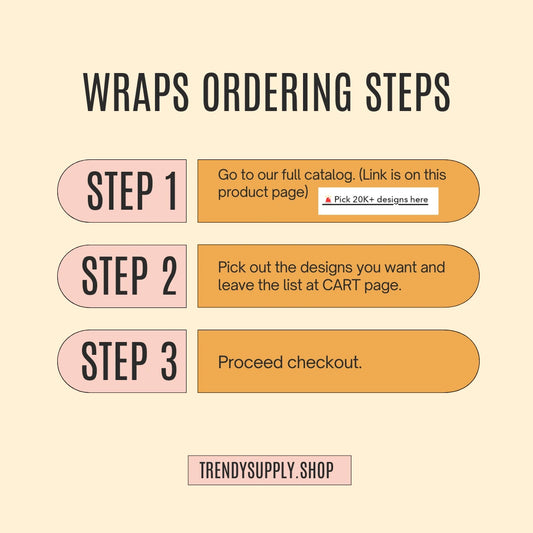

How to order Wholesale UV DTF Wraps? Step by step

Pick out the designs you want

Browse through our extensive catalog of pre - designed UV DTF wraps, which features a wide variety of themes, styles, and patterns. Whether you're looking for floral designs, geometric patterns, or custom - logo - ready templates, we have something to suit every taste and need. You can also submit your own custom design if you have a specific vision in mind. Our team of designers will review and ensure that the design is suitable for UV DTF printing.

Place the order on our website

Once you've selected the designs, add them to your cart and proceed to the checkout page. Enter your shipping address, contact information, and payment details securely. We accept a variety of payment methods, including credit cards, debit cards, and online payment platforms like PayPal. Review your order carefully to ensure that all the details are correct, and then click the “Place Order” button to finalize your purchase.

Printing and fast shipping

As soon as we receive your order, our experienced printing team will get to work. We use state - of - the - art UV DTF printing equipment and high - quality inks to ensure that your wraps are printed with the highest level of precision and color accuracy. Once the printing is complete, we carefully package your UV DTF wraps to protect them during transit. We offer fast shipping options, with most orders being dispatched within [X] business days. You'll receive a shipping confirmation email with a tracking number, allowing you to monitor the progress of your order until it arrives at your doorstep.

Frequently asked questions about applying UV DTF Wraps

How do I remove air bubbles during the application?

To remove air bubbles, start by applying the wrap slowly and using a squeegee or a credit card to smooth it out as you go. If air bubbles still appear, use a pin or a small needle to prick the bubble gently, then press the area flat with the squeegee to push out the air.

Can UV DTF wraps be applied to curved surfaces?

Yes, UV DTF wraps are highly adaptable and can be applied to curved surfaces like cups, bowls, and vases. The key is to apply the wrap carefully, using heat and pressure to conform it to the shape of the surface. A heat gun can be especially useful for working with curved substrates.

How long do UV DTF wraps last?

With proper care, UV DTF wraps can last for several years. Avoid exposing the wrapped items to excessive heat, sharp objects, and harsh chemicals. Regular hand - washing with mild soap and water is usually sufficient for cleaning without damaging the wrap.

Conclusion: Master UV DTF Wraps and Elevate Your Craft

In conclusion, learning how to make UV DTF wraps is a valuable skill that can open up a world of creative and business opportunities. Whether you're a hobbyist looking to add a new dimension to your crafts or a business owner aiming to offer unique, high - quality products, UV DTF wraps offer endless possibilities. From their high - quality prints and versatility to their durability and cost - effectiveness, UV DTF wraps are truly a game - changer in the world of custom printing.

Don't miss out on the chance to enhance your craft or business. Explore our range of UV DTF wraps and start creating stunning, personalized products today. Whether you're ordering wholesale for your business or looking to try out the process for yourself, we're here to support you every step of the way. Place your order now and take the first step towards mastering the art of UV DTF wrapping!