UV DTF tumbler wraps are rapidly gaining popularity in the personalized drinkware market. As the personalized gift market is booming with an estimated annual growth rate of 8.8%, this guide will walk you through everything you need to know, from understanding what they are to mastering the application process. Get ready to transform ordinary tumblers into stunning, personalized masterpieces!

What are UV DTF Tumbler Wraps?

UV DTF tumbler wraps are custom-designed graphics printed onto a special film using UV (ultraviolet) printing technology. These wraps are designed to be transferred onto tumblers (and other objects) to create vibrant, durable, and personalized decorations. The UV printing process ensures the designs are high-quality, resistant to fading, and long-lasting. Unlike traditional methods, UV DTF doesn't require heat for application, making it a simpler and more versatile option.

Why are UV DTF Tumbler Wraps so Popular?

UV DTF tumbler wraps have gained significant popularity among crafters and DIY enthusiasts for several reasons:

Vibrant and Durable Designs

UV printing produces products that are resistant to scratching, fading, and water damage. The UV curing process creates a strong bond, ensuring the designs remain vibrant and intact even with regular use and washing. This durability is a significant advantage over other methods that may result in peeling or fading over time.

Easy Application

Compared to other methods like sublimation or heat transfer vinyl, UV DTF wraps are relatively easy to apply, requiring no special equipment like heat presses. This ease of application makes them accessible to a wider range of users, from beginners to experienced crafters. The process is also less time-consuming and less prone to errors than other methods.

Versatility

They can be applied to a variety of smooth, hard surfaces, including glass, plastic, and metal tumblers. This versatility expands the creative possibilities, allowing users to personalize a wide array of drinkware and other items. The wraps conform well to different shapes, making them suitable for various tumbler styles.

Customization

UV DTF wraps offer endless possibilities for customization, allowing for intricate designs, full-color images, and personalized touches. The high resolution of UV printing allows for fine details and complex graphics, enabling users to create truly unique and personalized items. This level of customization is unmatched by many other decoration methods.

No Weeding

Unlike vinyl, there's no need to "weed" away excess material, saving time and effort. This eliminates a tedious and often frustrating step in the crafting process, making UV DTF wraps a more efficient and enjoyable option. The lack of weeding also reduces material waste.

How Can Crafters Benefit from UV DTF Tumbler Wraps?

Crafters can benefit from UV DTF tumbler wraps in numerous ways:

Enhanced Creativity

UV DTF allows for more complex and detailed designs than other methods. The ability to reproduce fine lines, gradients, and intricate patterns opens up a new world of design possibilities for crafters. They are no longer limited by the constraints of traditional methods and can express their artistic vision with greater freedom and precision.

Time Efficiency

The application process is quicker and easier, allowing crafters to produce more tumblers in less time. The streamlined workflow, from design to application, significantly reduces production time. This efficiency allows crafters to fulfill larger orders, experiment with more designs, and ultimately increase their output without sacrificing quality.

Professional Results

UV DTF wraps provide a high-quality, professional finish that enhances the value of their products. The smooth, vibrant, and durable finish of UV DTF wraps elevates the perceived value of the final product. This professional look enhances customer satisfaction and allows crafters to command higher prices for their creations.

Expanded Product Offerings

Crafters can offer a wider variety of personalized tumblers with unique and eye-catching designs. With UV DTF, crafters can cater to diverse customer tastes and preferences, offering a broader range of designs, styles, and themes. This versatility attracts a larger customer base and increases the potential for sales and growth.

Increased Profitability

The ability to create high-quality, customized tumblers can lead to increased sales and profits. By offering unique, high-value products, crafters can justify higher prices and increase their profit margins. The efficiency of the UV DTF process also reduces production costs, further contributing to increased profitability.

How to Make UV DTF Tumbler Wraps?

The process of creating UV DTF tumbler wraps involves specialized equipment, specifically a UV printer. Here's a more detailed breakdown:

Design Creation

A digital design is created using graphic design software. This stage involves using software like Adobe Illustrator or Photoshop to create the desired image. Factors such as image resolution, color accuracy, and design size are crucial for a high-quality final product.

Printing

The design is printed onto a special film using a UV printer and UV ink. UV printers use ultraviolet light to cure the ink as it is printed, resulting in a durable, vibrant image. The type of UV printer and ink used can affect the final quality and durability of the wrap.

Lamination

A laminate film is applied to protect the design. This lamination process adds a protective layer over the printed design, enhancing its resistance to scratches, abrasion, and other forms of wear and tear. It also contributes to the overall look and feel of the final product.

Transfer

The design is then transferred from the film to the tumbler. This involves carefully applying the printed and laminated film to the tumbler surface, ensuring proper alignment and adhesion. Techniques like using a squeegee to remove air bubbles and ensure a smooth application are often employed.

Most crafters find it easier to purchase pre-printed UV DTF wraps from suppliers.

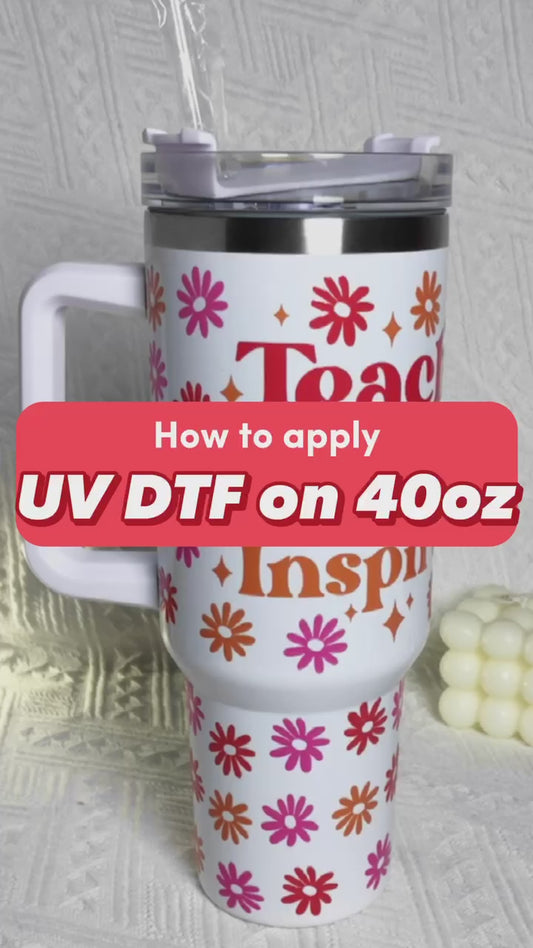

How to Apply UV DTF Tumbler Wraps

Applying UV DTF wraps is a relatively simple process:

1. Prepare the Tumbler

Ensure the tumbler is clean, dry, and free of any dust or debris.

2. Position the Wrap

Carefully align the UV DTF wrap on the tumbler.

3. Adhere the Wrap

Press the wrap firmly, smoothing out any bubbles or wrinkles.

4. Remove the Film

Gently peel off the protective film, leaving the design on the tumbler.

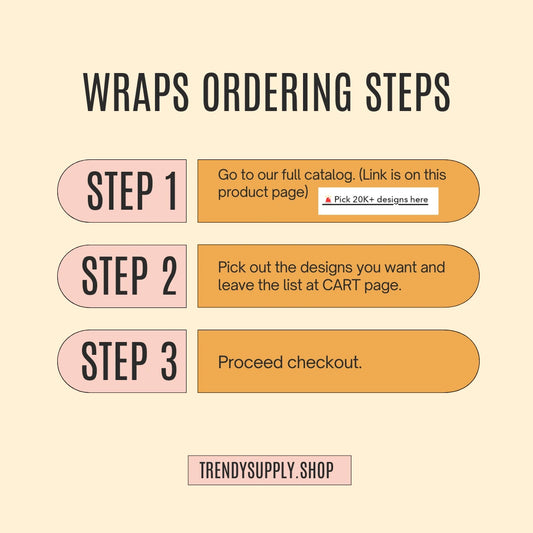

How to Order UV DTF Tumbler Wraps? Step by Step

Ordering UV DTF tumbler wraps is a straightforward process:

Pick Out the Designs You Want

Browse a supplier's website or catalog and select from a variety of designs or upload your own custom designs.

Place the Order on Our Website

Add your chosen designs and the desired quantity to your cart and proceed to checkout.

Printing and Fast Shipping

The supplier will print your designs using UV DTF technology and ship them to you.

Frequently Asked Questions About Applying UV DTF Tumbler Wraps

Are UV DTF tumbler wraps permanent?

They are very durable, but can be removed with some effort.

Can UV DTF tumbler wraps be used on any tumbler?

They work best on smooth, hard surfaces like glass, metal, and some plastics.

Are UV DTF tumbler wraps dishwasher safe?

Hand washing is recommended to prolong the life of the design.

Do I need any special tools to apply UV DTF tumbler wraps?

A squeegee can be helpful for smoothing out the wrap.

Wrap It Up! Your Tumbler Transformation Awaits

UV DTF tumbler wraps offer a fantastic way to personalize tumblers with vibrant, durable designs. Whether you're a seasoned crafter or just starting out, this method provides a simple and effective way to create stunning, customized drinkware.

Ready to get started? Explore our collection of UV DTF tumbler wraps and elevate your tumbler game today!