In a world that increasingly values personalization, UV DTF wraps have become a go-to solution for creating vibrant, long-lasting designs on cups and drinkware. With analysts predicting that until 2030, the market for custom printed items will expand at a compound annual growth rate of 26%, more businesses and individuals are turning to UV DTF technology to make their products stand out. These wraps, crafted with UV-curable inks and specialized films, offer a high-quality, durable option that withstands wear, water, and time. Let’s dive into how UV DTF wraps work, how to apply them, and why they’re a top choice for customization today.

What are UV DTF Wraps?

UV DTF (Direct to Film) wraps represent a breakthrough in printing technology, enabling vibrant and durable designs on drinkware and other items. This method utilizes UV-curable inks printed onto a special film and then transferred to a cup or similar object using heat and pressure. UV light instantly cures the ink, ensuring that designs maintain their brightness and can resist fading, scratching, and water damage. UV DTF wraps are ideal for creating personalized mugs, tumblers, and water bottles for gifts, promotions, or personal use.

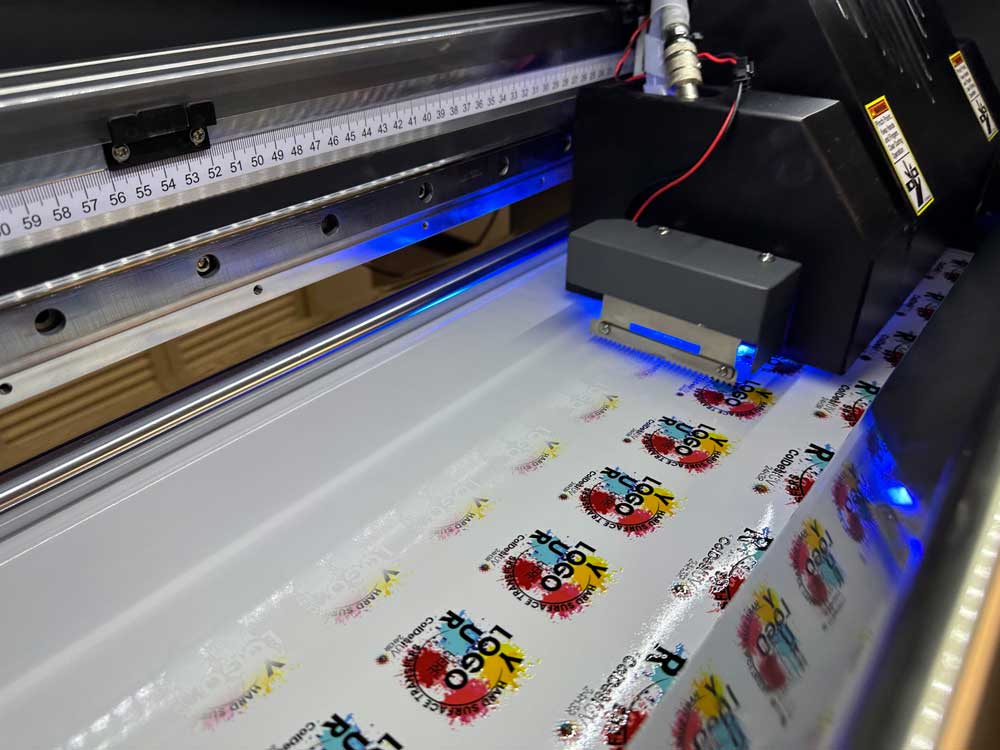

How to Make UV DTF Wraps?

Creating UV DTF wraps requires the right tools and a straightforward process. Here’s everything you need to get started.

To make UV DTF wraps, you’ll need:

- UV DTF printer: A specialized printer that uses UV-curable inks.

- UV DTF film/paper: Designed to hold and transfer your designs with clarity and durability.

- UV-curable inks: High-quality inks that set quickly under UV light.

- Design software: Use software like Adobe Illustrator or Photoshop to create and customize designs.

- UV curing light (optional): For additional curing after transfer, if necessary.

- Design Creation: Begin by creating your design using graphic design software. Make sure it’s the right size and resolution for your item.

- Printing: Load the UV DTF paper into your printer and print the design using UV-curable inks. The ink cures instantly under UV light, making the print ready for transfer.

- Lamination (if needed): Some UV DTF wraps may require a clear film laminated over the design to protect it during transfer.

- Transfer Application: Remove the backing from the UV DTF wrap, align it with your item, and press it onto the surface to adhere the design.

- Optional UV Curing: For additional durability, use a UV curing light to ensure the ink is fully set and long-lasting.

As you can see, it’s quite a hassle and expensive to print uv dtf wraps yourself. So a lot of people will opt to find a print house or a manufacturer like us to print the uv dtf wraps for them.

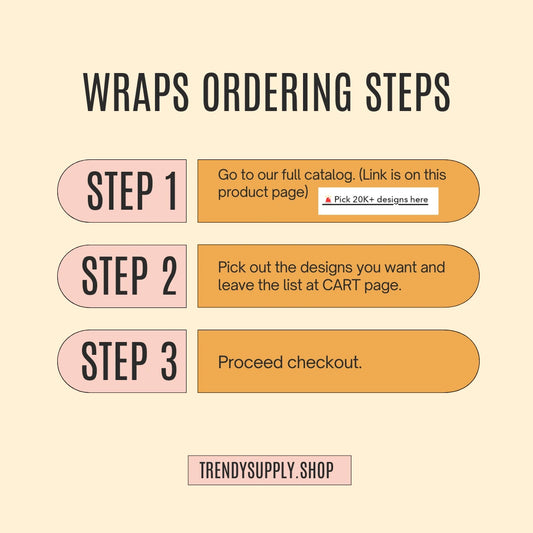

Not only do we offer in-house uv dtf printing to print your custom designs, we also offer an amazing uv dtf wraps catalog with over 20,000 designs for you to choose. Check out our premium quality 16oz uv dtf wraps now!

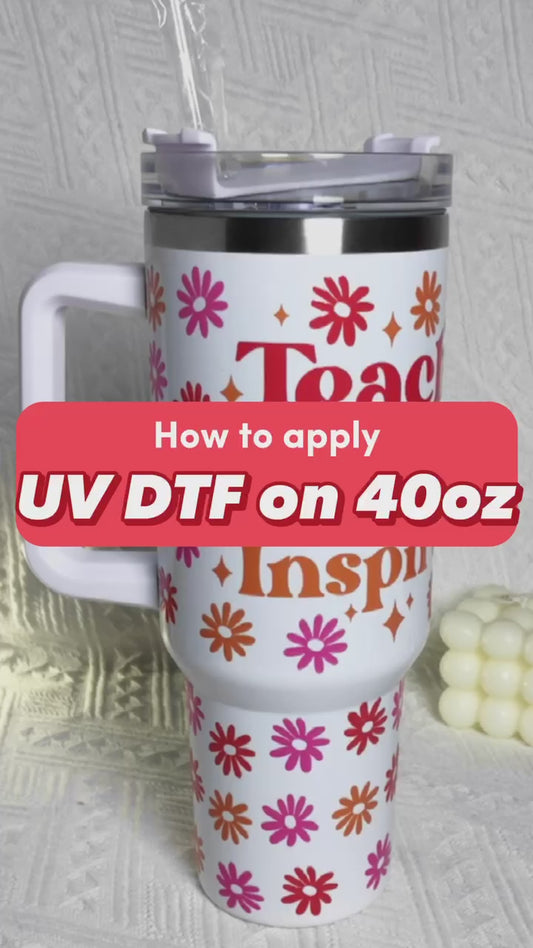

Once you have the uv dtf wraps you want, let’s see how to apply them to cups.

Tools You Need to Apply UV DTF Wraps

To achieve the best results when applying UV DTF wraps, it’s essential to use the right tools. Here’s what you’ll need:

UV DTF WrapsStart with high-quality UV DTF wraps that suit your design and project needs. These wraps come in a variety of colors and patterns, providing endless options for customization.

Cup BlanksChoose a cup or tumbler blank with a smooth surface that’s compatible with UV DTF wraps. The material should allow for secure adhesion of the wrap to ensure a lasting design.

We offer an extensive cup blanks for you to choose. Glass cans, acrylic cups, snow globe glass cans are all popular options clients love. Browse our website for more information.

Squeegee or Burnishing Tool

A squeegee or burnishing tool is essential for applying even pressure to the wrap, eliminating air bubbles, and ensuring a smooth, professional finish. This step helps the wrap bond securely to the cup for long-lasting results.

How to Apply UV DTF Wraps? Step by Step

Applying UV DTF wraps is simple with the right technique:

Step One: Prepare the Surface

Ensure the cup surface is clean, smooth, and dry. This helps the design adhere firmly to the cup.

Step Two: Trim and Align the Wrap

Trim the edges of the wrap to ensure it fits perfectly. Align the design carefully, starting from one edge to avoid air bubbles.

Step Three: Stick and Rub

Press the wrap onto the cup with even pressure, using a squeegee or burnishing tool to smooth it out. Begin at one end and work toward the other, ensuring no air pockets.

Tips for Successful Application

- Cleanliness: Make sure the cup is free from dust and oils.

- Steady Pressure: Apply consistent pressure to ensure even adhesion.

- Check Alignment: Position the wrap carefully to avoid misalignment.

- Peel Carefully: When peeling the film, do it slowly to avoid lifting the design.

Are UV DTF Wraps Waterproof?

Yes, UV DTF wraps are generally waterproof! The UV-curable inks create a strong, water-resistant bond when cured, making them ideal for everyday use with beverages. However, for best results, avoid exposing them to harsh chemicals or abrasive scrubbing, which can shorten their lifespan.

Are UV DTF Wraps Dishwashers Safe?

UV DTF wraps are durable but are not recommended for dishwashers. The high temperatures and powerful detergents used in dishwashers can cause the designs to fade or peel over time. To keep your designs looking vibrant, hand wash your UV DTF-wrapped items with mild soap and warm water.

How Much Do UV DTF Wraps Cost?

The cost of UV DTF wraps varies depending on the materials and equipment used. While specialized UV DTF printers can be a significant initial investment, the overall process is cost-effective for creating custom designs in bulk. If you’re outsourcing the printing, individual wraps may range from a few cents to a few dollars each, depending on the quality and complexity of the design.

Here, we offer premium quality uv dtf wraps with amazing wholesale price. Check our pricing on the 16oz uv dtf wraps product page here.

How to Make Customized UV DTF Wraps?

Creating customized UV DTF wraps allows you to craft unique and personalized designs. Follow these steps:

- Design Your Artwork – Using software, create a design that reflects your desired style or branding.

- Select Premium UV DTF Film – Choose from standard, premium, or specialty films like metallic or glitter finishes for added flair.

- Print and Apply – Print the design onto UV DTF film, apply it to your cup, and peel the film carefully to reveal your custom design.

Here, we offer custom uv dtf wraps printing with amazing wholesale prices as well. All you need to do is send us your image in a transparent background and we’ll print them for you. For more information, please check our 16oz uv dtf wraps product page.

Conclusion: Embrace the Durability and Style of UV DTF Wraps

UV DTF wraps are the perfect blend of durability, vivid color, and customizability, transforming ordinary drinkware into unique, standout pieces. With simple application steps and waterproof, long-lasting designs, UV DTF wraps meet both personal and business customization needs. Whether you're creating a personalized gift, enhancing your brand, or adding flair to your drinkware collection, these wraps deliver professional-quality results that last.

Ready to elevate your drinkware? Check out our amazing UV DTF wraps collection and find the perfect UV DTF wraps to realize your creative visions, boost sales and skyrocket profits!