UV DTF Wraps how to use is one of the most asked questions. The world of custom printing has witnessed a significant transformation with the rise of UV DTF wraps. According to a recent report from the Printing Industry Association, the use of DTF (Direct-to-Film) market size, including UV DTF wraps, was estimated to be $2.72 Billion in 2024- scale crafters and large - scale businesses alike. These innovative wraps offer a versatile and high - quality way to add custom designs to a variety of surfaces. Whether you're a seasoned crafter looking to expand your creative horizons or a business owner aiming to enhance your product branding, understanding how to use UV DTF wraps is key to unlocking their full potential.

What are UV DTF Wraps?

Definition and Basics

UV DTF wraps are a type of printing technology that involves transferring high - resolution, full - color designs from a film onto various substrates. The "DTF" stands for Direct-to-Film, where the design is first printed onto a PET (polyethylene terephthalate) film using specialized DTF printers. After printing, a layer of UV - curable adhesive is applied over the design. The UV curing process uses ultraviolet light to instantly dry and harden the adhesive and ink, creating a durable and vibrant transfer. Once cured, the design on the film can be easily transferred onto surfaces such as clothing, accessories, home decor items, and even promotional products.

Key Components

-

Ink: UV DTF wraps use special UV - curable inks. These inks are formulated to dry quickly under UV light, resulting in sharp, vivid colors and excellent colorfastness. The inks are also designed to adhere well to both the film and the final substrate, ensuring a long - lasting print.

-

PET Film: The PET film serves as the base for the design during the printing process. It has a smooth surface that allows for precise ink deposition and provides a stable platform for the transfer. The film is thin, flexible, and transparent, making it easy to handle and position during the transfer process.

-

UV - Curable Adhesive: The adhesive is a crucial component of UV DTF wraps. It is applied over the printed design on the film and then cured using UV light. The cured adhesive acts as a strong bond between the design and the substrate, ensuring that the transfer adheres firmly and remains intact even after repeated use and washing.

Why are UV DTF Wraps so popular?

High - Quality Prints

One of the main reasons for the popularity of UV DTF wraps is the exceptional print quality they offer. The technology allows for the reproduction of intricate details, gradients, and fine lines with remarkable accuracy. Whether it's a photo - realistic image or a complex graphic design, UV DTF wraps can bring the design to life with vivid colors and sharp edges. This high - quality output makes them ideal for applications where a professional and eye - catching finish is required.

Versatility

UV DTF wraps are incredibly versatile, as they can be applied to a wide range of substrates. From cotton and polyester fabrics in the clothing industry to materials like wood, metal, plastic, and ceramic in the home decor and promotional product sectors, the possibilities are endless. This versatility makes UV DTF wraps a go - to choice for crafters and businesses looking to customize multiple types of products with the same design or a variety of different designs.

Durability

The UV curing process used in DTF wraps enhances the durability of the prints. The cured ink and adhesive form a protective layer that is resistant to fading, scratching, and peeling. This means that products with UV DTF wraps can withstand regular wear and tear, exposure to sunlight, and multiple wash cycles (in the case of clothing), making them a reliable option for long - lasting customizations.

How can crafters benefit from UV DTF Wraps?

Creative Freedom

For crafters, UV DTF wraps offer unparalleled creative freedom. They can easily bring their unique designs to life on various projects without being limited by traditional printing techniques. Crafters can use their own digital artwork or source designs from online platforms and then transfer them onto their chosen substrates with ease. This allows for the creation of one - of - a - kind handmade items, from custom - printed tote bags and jewelry to personalized home decor pieces.

Time and Cost Efficiency

Compared to some other custom printing methods, UV DTF wraps can be more time - and cost - efficient. The printing process on the film is relatively quick, and the transfer onto the substrate can be done in a matter of minutes. Additionally, since DTF printers can print multiple designs on a single sheet of film, crafters can produce small batches of different items without the need for expensive setup costs associated with traditional screen printing. This makes it a more accessible option for small - scale crafters who may have limited budgets and production capacities.

Business Expansion

For crafters looking to turn their hobby into a business, UV DTF wraps open up new opportunities for expansion. By offering custom - printed products using this technology, crafters can attract a wider customer base. They can take on custom orders for events, businesses, and individuals, increasing their revenue streams. The ability to produce high - quality, personalized products quickly and efficiently can also help build a good reputation and customer loyalty, further fueling business growth.

UV DTF Wraps how to use?

Preparation

-

Design Creation or Selection: Start by creating your own design using graphic design software like Adobe Photoshop or Illustrator. If you're not a designer, you can also find a wide range of pre - made designs on online marketplaces. Make sure the design is in a high - resolution format (at least 300 DPI) to ensure a sharp print.

-

Substrate Preparation: Clean and prepare the surface of the substrate you want to apply the wrap to. For fabric, ensure it is free of dirt, oils, and wrinkles. For hard surfaces like wood or metal, sand the surface lightly if necessary to create a better adhesion and then wipe it clean with a lint - free cloth.

Printing on Film

-

Load the PET Film: Insert the PET film into your DTF printer according to the manufacturer's instructions. Make sure the film is properly aligned to avoid any printing errors.

-

Print the Design: Set up the print settings on your DTF printer, including the print quality, color mode, and size. Send the design to the printer and let it print the design onto the film. Once the printing is complete, carefully remove the film from the printer.

Applying the Adhesive and Curing

-

Apply the UV - Curable Adhesive: Using a specialized adhesive applicator or a spray gun, apply an even layer of UV - curable adhesive over the printed design on the film. Make sure to cover the entire design area completely.

-

UV Curing: Place the film with the adhesive - coated design under a UV curing machine. The UV light will cure the adhesive and ink within seconds, hardening the layer and making it ready for transfer.

Transferring the Wrap

-

Position the Film: Carefully position the film with the cured design on the substrate. Make sure it is aligned correctly and there are no air bubbles or wrinkles. You can use a heat press or a flat iron set to a low temperature to apply gentle pressure and help with the transfer.

-

Peel Off the Film: Once the film has been heated and adhered to the substrate, slowly peel off the PET film from one corner. The design, along with the cured adhesive, will be transferred onto the substrate, leaving a vibrant and durable print.

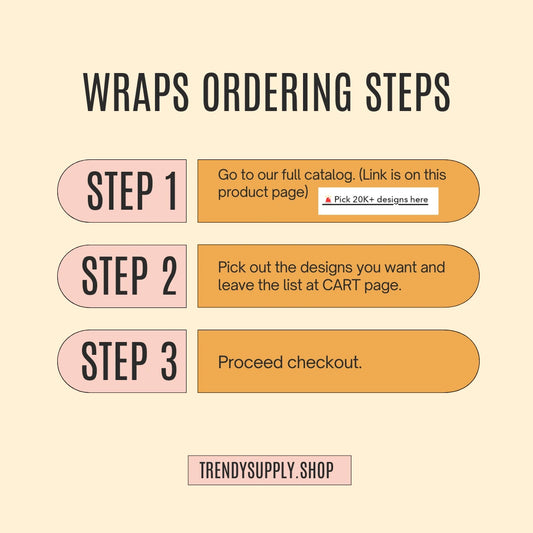

How to order Wholesale UV DTF Wraps? Step by step

Pick out the designs you want

Browse through our extensive catalog of UV DTF wrap designs. We offer a wide variety of options, from trendy patterns and graphics to customizable templates. You can filter the designs by category, style, or theme to easily find the ones that suit your needs. If you have a specific design in mind, you can also submit your own artwork for a custom - printed order.

Place the order on our website

Once you've selected the designs, add them to your cart. Specify the quantity of each design you require, as well as any additional details such as the size of the wraps. Review your order carefully to ensure all the details are correct, including the shipping address and payment information. Then, proceed to checkout and complete the order process.

Printing and fast shipping

After receiving your order, our team of experts will immediately start the printing process. We use state - of - the - art DTF printers and high - quality materials to ensure the prints meet our strict quality standards. Once the printing is complete, we will carefully package your UV DTF wraps and ship them to you using a fast and reliable shipping service. You can track your order online to stay updated on its delivery status.

Frequently asked questions about applying UV DTF Wraps

What temperature should I use when heat - pressing the wrap?

The ideal temperature for heat - pressing UV DTF wraps can vary depending on the substrate and the type of adhesive used. As a general guideline, for fabric substrates, a temperature range of 150 - 180°C (302 - 356°F) is usually recommended. However, it's always best to refer to the manufacturer's instructions for the specific UV DTF wrap product you are using.

Can I apply UV DTF Wraps to stretchy fabrics?

Yes, you can apply UV DTF wraps to stretchy fabrics. However, it's important to use a stretch - friendly adhesive and to apply gentle pressure during the transfer process to prevent the design from cracking or peeling when the fabric stretches. You may also want to pre - stretch the fabric slightly before applying the wrap to ensure a better fit.

How do I remove a UV DTF Wrap if I make a mistake during application?

If you make a mistake during the application process and need to remove the UV DTF wrap, it's best to do so as soon as possible while the adhesive is still somewhat malleable. Gently peel off the wrap from one corner, using a plastic scraper or your fingernail to help lift it if necessary. Be careful not to damage the substrate during the removal process. If the adhesive leaves any residue, you can try using a mild adhesive remover or rubbing alcohol to clean the surface.

Conclusion: Unlock the Potential of UV DTF Wraps Today!

In conclusion, UV DTF wraps offer a world of possibilities for crafters, businesses, and anyone looking to add a personal touch to their products. With their high - quality prints, versatility, and durability, they have become an essential tool in the custom printing industry. Whether you're just starting out or looking to take your customizing skills to the next level, learning how to use UV DTF wraps and ordering them wholesale from our reliable service can open up new creative and business opportunities. Don't wait any longer! Explore our collection of UV DTF wraps, place your order, and start creating stunning, personalized items that will stand out from the crowd.