What is DTF transfer? It's a digital printing method that's revolutionizing custom apparel and merchandise. The global digital textile printing market is experiencing explosive growth, a testament to the surging demand for personalized items. Projections indicate it will reach significant heights by 2028. To be specific, reports show the global digital textile printing market size is estimated to reach USD 9.51 Billion by 2032. This surge is driven by DTF (Direct-to-Film) transfer printing which stands at the forefront of this movement, offering a technology that's rapidly transforming the way we create custom designs. If you're looking to understand the core of this printing technique, you're in the right place. This comprehensive guide will explain everything, from the process's fundamentals to its extensive applications in crafting and business.

What is DTF Transfer?

DTF transfer is a digital printing method where designs are printed onto a specialized film, which is then transferred onto various fabrics and materials using heat. Unlike traditional screen printing, DTF printing allows for full-color, high-resolution prints on a wide range of surfaces, including cotton, polyester, blends, and even non-textile items. The process involves printing the design onto a DTF film, applying a heat-activated adhesive powder, and then heat-pressing the design onto the desired substrate.

Why is DTF Transfer so popular?

Versatility: Adapts to Various Needs

DTF transfer works on a variety of fabrics and materials, eliminating the limitations of traditional printing methods.

High-Quality Prints: Stunning Results

DTF produces vibrant, detailed, and durable prints with a soft hand feel.

Cost-Effectiveness: Budget-Friendly Customization

It eliminates the need for screens and complex setups, making it ideal for small batches and custom orders.

Quick Turnaround: Fast and Efficient

The process is relatively fast, allowing for efficient production times.

Full-Color Printing: Unlimited Color Options

DTF allows for gradient prints and unlimited color options without additional costs.

How can crafters benefit from DTF transfer?

Personalized Products

Create custom apparel, accessories, and home decor items with unique designs. Imagine designing personalized t-shirts for family reunions, customized tote bags for bridal showers, or unique pillow covers for home decoration. DTF transfers empower crafters to bring their creative visions to life and offer truly one-of-a-kind items to their customers.

Small-Batch Production

Produce limited-edition items or custom orders without high setup costs. This is particularly advantageous for crafters who want to test new designs or cater to niche markets. With DTF transfers, you can create small quantities of unique items without incurring significant upfront expenses, allowing you to experiment with different styles and cater to specific customer demands.

Diverse Applications

Apply designs to a wide range of materials, expanding your crafting options. Beyond traditional fabrics, DTF transfers can be applied to leather, wood, canvas, and even ceramic surfaces. This versatility opens up a world of possibilities for crafters, allowing them to create a diverse range of products and cater to a wider audience.

Enhanced Creativity

Bring intricate designs and vibrant colors to your projects with ease. DTF transfers allow for the reproduction of highly detailed artwork, complex patterns, and photographic images. This level of detail and color vibrancy enhances the visual appeal of your projects, making them stand out from the crowd. Crafters can now bring their most ambitious designs to life with stunning clarity and precision.

Professional Results

Achieve high-quality, durable prints that elevate your craft. The prints produced using DTF transfers are known for their exceptional durability, resistance to fading, and soft hand feel. This ensures that your creations not only look professional but also withstand the test of time. Your customers will appreciate the high quality of your work, leading to increased satisfaction and repeat business. Crafters can now confidently offer professional-grade products that meet the highest standards of quality and durability.

How to make DTF Transfers?

Making DTF transfers involves a meticulous process that combines digital printing technology with specialized materials:

Design Creation: Unleashing Your Creativity

-

Begin by creating your desired design using graphic design software. This is your starting point, the foundation upon which your DTF transfer will be built. Ensure your design is high-resolution and optimized for printing to achieve the best possible results.

Printing: Bringing Your Design to Life

-

The heart of the DTF process lies in the printing stage. Load the specialized DTF film into a dedicated DTF printer. This film acts as the canvas for your design. Using specialized DTF ink, print your design onto the matte side of the film. This ink is formulated to interact perfectly with the subsequent steps in the process.

Powder Application: The Adhesive Key

-

Once the design is printed, a crucial step involves applying a heat-activated adhesive powder evenly over the wet ink. This powder is the secret ingredient that will enable the transfer to adhere securely to the fabric or material. Carefully distribute the powder, ensuring all areas of the printed design are adequately covered. Gently shake off any excess powder to prevent clumping or uneven application.

Powder Curing: Setting the Stage

-

The next step is to cure the powder, transforming it from a loose powder into a flexible adhesive layer. This is typically achieved using a heat press or a dedicated powder curing oven. Follow the specific instructions provided by the equipment manufacturer regarding temperature and time settings to ensure optimal curing results. This step is critical for the success of the transfer process as it solidifies the bond between the design and the adhesive.

Transfer: Ready to Press

-

Once the powder is cured, your DTF transfer is ready for application. This stage involves carefully positioning the transfer onto the desired material and applying heat and pressure to fuse the design to the fabric or material. This process will be detailed further in the following section on "How to Press DTF Transfers."

How to press DTF Transfers? Step by step

Pressing DTF transfers requires a heat press and careful execution, broken down into detailed steps:

1. Prepare the Material: A Clean Slate

-

Ensure the garment or material is clean and wrinkle-free.

-

Pre-pressing the item for a few seconds can help remove any moisture or wrinkles.

-

This will ensure the DTF transfer adheres properly and results in a smooth, even print.

2. Position the Transfer: Precision Placement

-

Carefully position the DTF transfer onto the desired location on the garment or material.

-

Use a ruler or measuring tape to ensure accurate placement and alignment.

-

Consider using heat-resistant tape to secure the transfer in place and prevent it from shifting during the pressing process.

3. Heat Press: The Magic of Heat and Pressure

-

Apply heat and pressure using a heat press according to the manufacturer's instructions for the specific type of DTF transfer and material being used.

-

The recommended temperature and pressure settings will vary depending on the product.

-

Ensure even pressure is applied across the entire transfer area.

4. Cool Peel: Patience is Key

-

Allow the transfer to cool completely before carefully peeling off the film.

-

Peeling the film while it's still hot can result in smudging or damage to the print.

-

Once the transfer has cooled, gently peel off the film, starting from one corner and working your way across.

5. Final Press (Optional): Enhancing Durability and Feel

-

A brief second press, often with a silicone sheet or parchment paper placed over the design, can enhance the durability and feel of the print.

-

This helps to further set the ink and create a smoother, softer finish.

-

Follow the manufacturer's recommendations for the time and temperature of the final press.

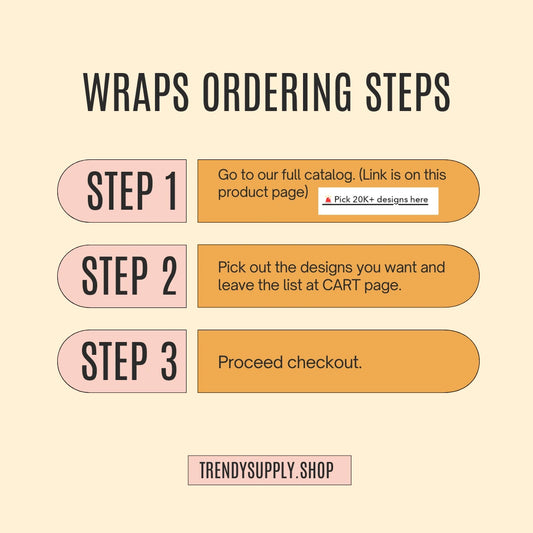

How to order wholesale DTF Transfer? Step by step

Ordering wholesale DTF transfers is a straightforward process:

Pick out the designs you want

-

Browse the supplier's catalog or submit your custom designs.

-

Consider the size, color, and complexity of your designs.

Place the order on our website

-

Add your chosen designs and quantities to your cart.

-

Provide any necessary specifications or instructions.

-

Double check all information.

Printing and fast shipping

-

The supplier will print and prepare your DTF transfers.

-

Enjoy fast shipping or local pickup for quick turnaround times.

Frequently asked questions about DTF Transfer

What fabrics can DTF transfers be used on?

DTF works on cotton, polyester, blends, and many other materials.

Are DTF transfers durable?

Yes, DTF prints are highly durable and resistant to cracking and fading.

Can I print full-color designs?

Yes, DTF allows for full-color printing with gradients.

What equipment is needed for DTF printing?

-

A DTF printer

-

DTF ink

-

DTF film

-

Adhesive powder

-

A heat press

Unlock Your Creative Potential with DTF Transfers!

DTF transfer printing is a game-changer for anyone looking to create custom apparel and merchandise. Its versatility, quality, and ease of use make it an ideal solution for crafters, small businesses, and large-scale operations.

Ready to experience the benefits of DTF transfers? Explore our wholesale options and start creating your own custom designs today!